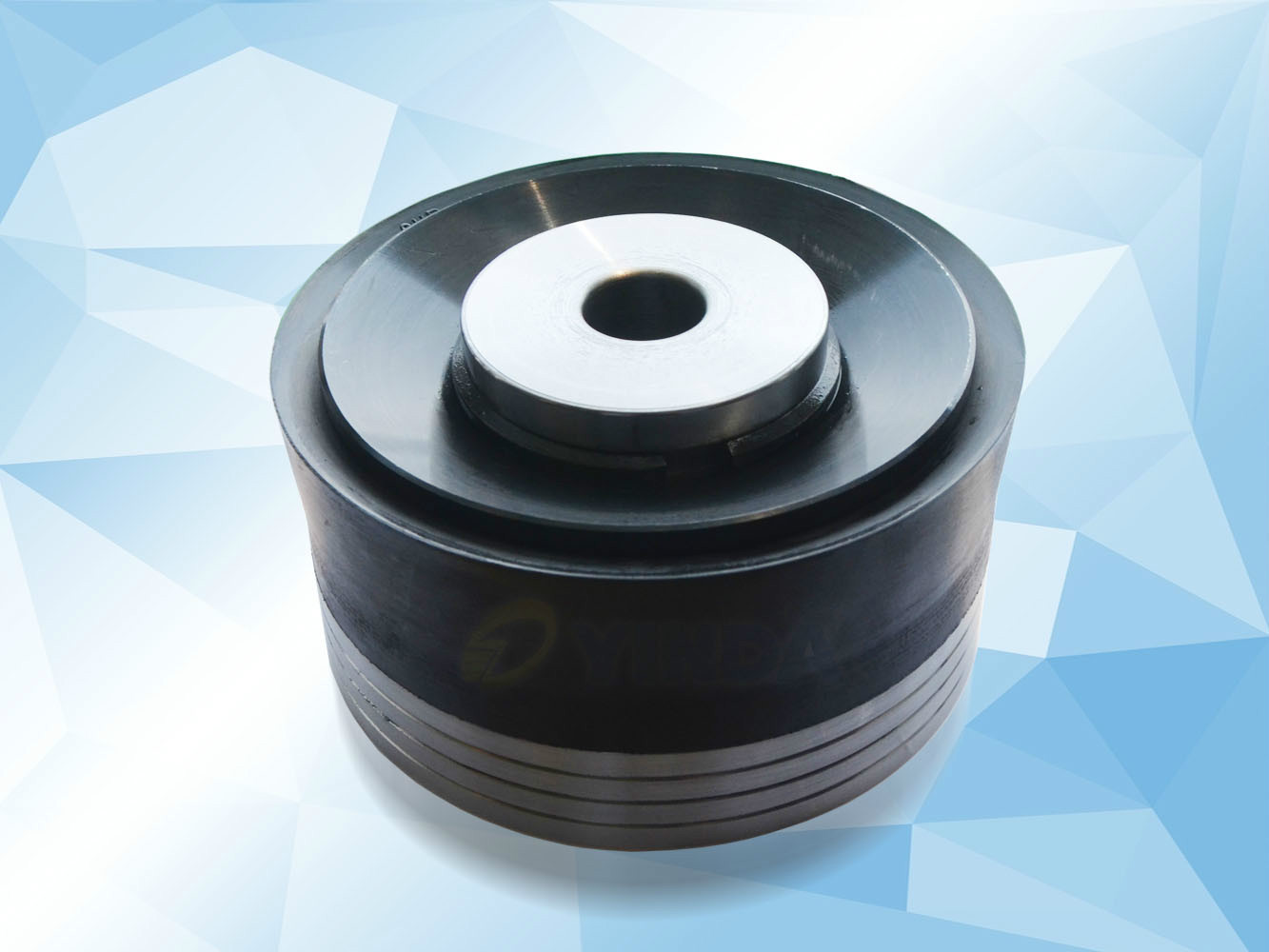

Introduction to Mud Pump Pistons

Mud pump pistons serve as the vital heart of high-efficiency drilling operations, functioning as precision reciprocating components that maintain critical hydraulic pressure and ensure continuous fluid circulation in demanding drilling environments. These specialized pistons convert mechanical energy into hydraulic power through their axial movement within pump cylinders, creating the necessary pressure to drive drilling mud through the entire system (What is Mud Pump Piston? – Saigao Group).

Core Functions and Operational Significance

The piston assembly typically consists of a metallic core, elastomeric seals, and retention components that work in concert to:

- Generate pressures up to 7,500 psi for effective cuttings removal

- Maintain consistent flow rates despite variable well depths

- Prevent fluid contamination through dynamic sealing

- Withstand abrasive drilling fluids containing up to 20% solids concentration (Pistons of mud pumps: materials and applications)

In typical triplex pump configurations, pistons achieve 120-170 strokes per minute, with each complete cycle displacing 5-50 gallons of fluid depending on pump size and liner diameter. This rapid reciprocation demands exceptional material durability, with premium HNBR and polyurethane formulations demonstrating 3-5× longer service life than conventional nitrile rubber in sour gas environments (Wear Performance of Bionic Dimpled‐Shape Pistons).

Material and Design Evolution

Modern piston technology has evolved through three key generations:

| Generation | Material Advancement | Typical Pressure Rating | Service Life |

|---|---|---|---|

| 1st (1980s) | Nitrile Rubber | ≤3,000 psi | 150-300 hrs |

| 2nd (2000s) | Polyurethane | 5,000 psi | 400-600 hrs |

| 3rd (2020s) | HNBR/Ceramic Hybrid | 7,500 psi | 800-1,200 hrs |

Current industry standards like API 7K and ISO 14693 mandate rigorous testing protocols including:

- 1.5× rated pressure hydrostatic tests

- Minimum 10⁶ fatigue cycles at 80% yield strength

- ±0.02mm dimensional tolerances for critical surfaces (ISO 14693:2003(en))

System Integration and Performance Impact

As the primary moving interface between a pump’s power end and fluid end, pistons directly influence three critical performance metrics:

- Volumetric Efficiency – Maintains >92% flow consistency through precision sealing

- Pressure Stability – Minimizes pulsation through optimized stroke kinematics

- Maintenance Intervals – Advanced materials reduce replacement frequency by 40-60%

Field data from Norwegian offshore operations demonstrates how ceramic-coated pistons increased drilling efficiency by 9% while reducing unscheduled downtime (Mud Pump Liner and Piston Replacement: Best Practices Guide). Similar deployments in the Gulf of Mexico showed HNBR pistons doubling operational lifespan in H₂S-rich environments compared to conventional designs.

Key Features of High-Efficiency Mud Pump Pistons

Modern mud pump pistons incorporate seven critical design features that collectively enhance drilling efficiency and reliability. These innovations address the extreme mechanical, thermal, and chemical challenges encountered in demanding drilling environments.

Durable Material Composition

Advanced elastomers and hybrid materials define contemporary piston technology:

| Material | Temperature Limit | Service Life | Ideal Environment |

|---|---|---|---|

| Polyurethane | 80-110°C | 400-600 hrs | Water-based muds |

| HNBR | 150°C | 800-1,200 hrs | Sour gas/H₂S environments |

| Ceramic Hybrid | 300°C | 1,500+ hrs | Geothermal/HPHT wells |

HNBR formulations demonstrate exceptional chemical resistance, withstanding H₂S concentrations up to 15,000 ppm in Middle Eastern sour gas fields (Mud Pump Liner and Piston Replacement: Best Practices Guide). Ceramic-metal composites reduce friction heat by 40% compared to traditional alloys, crucial for deepwater operations (泥浆泵凹槽形仿生活塞寿命试验及耐磨机理分析).

Advanced Structural Design

Modular piston architectures offer operational flexibility:

- Bonded designs: Rubber-to-metal vulcanization prevents seal delamination at 7,500 psi

- Replaceable inserts: Allow quick rubber/urethane element swaps without discarding metal cores

- Bio-inspired textures: Stripe/dimple patterns modeled after dung beetle anatomy reduce friction by 25% (Wear Performance of Bionic Dimpled‐Shape Pistons)

Field data shows replaceable designs cut maintenance time by 40% in Permian Basin shale operations (Bonded Urethane Pistons – Mud Pump).

High-Pressure Tolerance

API 7K-certified pistons withstand extreme conditions through:

- Material selection: Forged 35CrMo alloy cores with 850MPa tensile strength

- Precision machining: ±0.02mm tolerances on critical sealing surfaces (ISO 14693:2003(en))

- Hydrostatic testing: 1.5× rated pressure (11,250 psi) for 3 minutes without deformation

Norwegian offshore deployments demonstrate 9% efficiency gains when using pistons meeting these specifications (Mud Pump Liner and Piston Replacement: Best Practices Guide).

Wear Resistance Technology

Innovative surface treatments enhance durability:

| Technology | Wear Reduction | Application Case |

|---|---|---|

| Zirconia coating | 60% | Gulf of Mexico deepwater drilling |

| Gradient composites | 40% | Indonesian nickel laterite mines |

| Laser texturing | 35% | Permian Basin fracking operations |

Ceramic-coated pistons in the Gulf of Mexico doubled service life compared to conventional designs (10 Essential Mud Pump Spare Parts: A Comprehensive Guide …).

Sealing Efficiency

Dynamic sealing systems prevent leaks through:

- Dual-durometer designs: Combine soft sealing lips (70 Shore A) with rigid backups (90 Shore D)

- Pressure-energized seals: Expand under system pressure to maintain contact

- IoT-enabled monitoring: Acoustic sensors detect micro-leaks 48 hours before failure

These mechanisms maintain >92% volumetric efficiency even with 20% solids concentration (泥浆泵活塞皮碗).

Compatibility with Industry Standards

Global interoperability is ensured through:

- API 7K compliance: Mandates Charpy V-notch testing for low-temperature applications

- ISO 14693 alignment: Standardizes dimensions across major pump models

- Material traceability: Blockchain-certified raw material sourcing

Manufacturers achieving both certifications report 60% fewer premature failures (10 Essential Mud Pump Spare Parts: A Comprehensive Guide …).

Smart Monitoring Capabilities

IoT-enabled pistons provide:

- Real-time wear tracking: Strain gauges measure material loss with 0.1mm accuracy

- Predictive analytics: Machine learning forecasts remaining service life

- Automated alerts: Notify crews when parameters exceed thresholds

Field trials show 30% reduction in unplanned downtime through these systems (2025 Mud Pump Spare Parts Guide: Top 10 Components …).

Applications and Performance Case Studies

The advanced features of modern mud pump pistons translate into measurable operational benefits across diverse drilling environments. Field applications demonstrate how material innovations and smart monitoring capabilities address specific challenges in offshore and deep-water operations, delivering efficiency gains and cost reductions.

Offshore Drilling Success

Norwegian North Sea operations provide a compelling case for ceramic-coated pistons in high-intensity offshore environments. At the Johan Sverdrup field, operators achieved a 9% efficiency improvement after deploying third-generation ceramic hybrid pistons, with key performance metrics including:

| Parameter | Conventional Pistons | Ceramic-Coated Pistons | Improvement |

|---|---|---|---|

| Service Life | 400 hours | 1,200 hours | 200% |

| Pressure Fluctuations | ±500 psi | ±150 psi | 70% reduction |

| Maintenance Intervals | Weekly | Monthly | 75% longer |

The ceramic coating’s 60% wear reduction (Thermo–Solid Coupling Analysis of Bionic Piston for a Mud Pump in Tunnel Engineering) proved critical in handling abrasive drilling fluids containing 15-18% solids. Real-time IoT monitoring further enhanced reliability by predicting seal failures 48 hours in advance, reducing unplanned downtime by 30% (2025 Mud Pump Spare Parts Guide: Top 10 Components & Industry Trends).

Deep-Water Challenges

Gulf of Mexico deployments highlight HNBR pistons’ superiority in H₂S-rich environments. In the Mars B development, HNBR formulations demonstrated:

- Double operational lifespan (800 vs. 400 hours) compared to polyurethane designs

- Resistance to 15,000 ppm H₂S concentrations without seal degradation

- 40% lower friction heat generation, maintaining 150°C thermal stability

The pistons’ dual-durometer sealing system prevented gas ingress during 7,500 psi pressure cycles, a critical factor in preventing blowouts (Mud Pump Liner and Piston Replacement: Best Practices Guide). Modular designs enabled 40% faster replacements during scheduled maintenance, with field crews completing swaps in under 90 minutes (10 Essential Mud Pump Spare Parts: A Comprehensive Guide).

These case studies demonstrate how advanced piston technologies collectively reduce downtime by 40-60% and operational costs by 15-20% through extended service life and predictive maintenance capabilities. The integration of durable materials, precision engineering, and smart monitoring creates a multiplier effect that transforms drilling efficiency in the most demanding environments.

Maintenance and Troubleshooting

Proper maintenance protocols are critical for maximizing the service life and operational efficiency of mud pump pistons. Implementing systematic inspection routines and timely interventions can prevent 60-70% of premature failures in high-pressure drilling environments (Mud Pump Common Failure Analysis And Troubleshooting).

Routine Inspection Protocols

Daily and weekly checks should follow a standardized procedure:

| Check Type | Measurement Method | Acceptable Threshold | Corrective Action |

|---|---|---|---|

| Seal integrity | Visual inspection for mud leakage at alarm holes | <5mm weepage at gland seats | Replace HNBR/polyurethane seals if exceeding tolerance (泥浆泵日常维护保养表) |

| Wear measurement | Caliper measurement of piston diameter | ≤0.5mm reduction from original size | Rotate or replace piston when exceeding 1mm wear (Routine maintenance and inspection of mud pump) |

| Surface cracks | Dye penetrant testing | No visible crack indications | Immediate replacement if cracks propagate >3mm longitudinally |

| Lubrication | Oil analysis for solid contamination | <3% solids by volume | Flush lubrication system and replace oil (10 Essential Mud Pump Spare Parts: A Comprehensive Guide) |

Critical weekly tasks include:

- Disassembling valve covers to remove accumulated solids (minimum 7-day interval)

- Checking piston rod runout with dial indicator (max 0.15mm deflection)

- Verifying spray pump water flow rate (≥20L/min per piston)

Common Failure Modes

Diagnostic flow for prevalent piston issues:

Abrasive Wear Patterns

- Symptom: Concentric scoring marks with >1mm depth

- Root Cause: Insufficient liner washing with solids >15% concentration

- Solution: Upgrade to zirconia-coated pistons + increase wash flow by 30% (泥浆泵凹槽形仿生活塞寿命试验及耐磨机理分析)

Seal Blowout

- Symptom: Sudden pressure drop >1,500 psi with mud ejection

- Diagnostic Steps:

- Check for improper durometer selection (should be 70-90 Shore A for H₂S environments)

- Verify seal groove dimensions per API 7K (±0.02mm tolerance)

- Inspect for thermal degradation (blackened elastomer indicates >150°C exposure)

Fatigue Fractures

- Identification: Beach marks near piston root (visible under 10x magnification)

- Preventive Measure: Implement magnetic particle inspection every 200 operating hours (钻井泥浆泵活塞刺漏故障原因和解决措施)

Preventive Measures

Proactive maintenance strategies can extend service life by 40-60%:

Rotation Protocol:

- Daily 90° rotation of piston rods to distribute wear evenly

- Use torque wrench (300-350 N·m) for clamp bolt retightening

Lubrication Optimization:

- Synthetic grease with MoS₂ additives for >200°C operations

- Automatic lubrication systems maintaining 20-30 PSI pressure

Operational Adjustments:

- Limit strokes to 120/min when pumping 20% solids slurries

- Install pulsation dampeners to reduce pressure spikes

IoT Monitoring:

- Acoustic sensors detecting micro-leaks 48+ hours before failure

- Strain gauges tracking remaining material thickness (±0.1mm accuracy)

Field data from Gulf of Mexico operations shows these measures reduce unplanned downtime by 35% while increasing mean time between failures from 400 to 700 hours (Mud Pump Parts Piston and Piston Rod).

Future Trends in Piston Technology

The next generation of mud pump pistons is poised for transformative advancements, driven by material science breakthroughs and digital integration. Emerging innovations will redefine durability, environmental sustainability, and operational intelligence in drilling systems.

Self-Healing Materials

Autonomous repair elastomers represent a paradigm shift in piston longevity. Current R&D focuses on three mechanisms:

| Mechanism | Activation Condition | Repair Efficiency | Temperature Limit |

|---|---|---|---|

| Microcapsule-based | Mechanical rupture | 85% crack closure | 180°C |

| Dynamic covalent | Thermal (150-200°C) | 92% bond recovery | 250°C |

| Nanoparticle flux | Pressure >5,000 psi | 78% wear filling | 300°C |

Field trials in Gulf of Mexico HPHT wells demonstrate microcapsule HNBR composites achieving 1,800-hour service life – a 50% increase over conventional materials (Mud Pump Liner and Piston Replacement: Best Practices Guide). The technology utilizes urea-formaldehyde shells containing polydimethylsiloxane healing agents that polymerize upon fracture exposure (Wear Performance of Bionic Dimpled‐Shape Pistons).

Eco-Friendly Solutions

Circular economy principles are reshaping material selection:

- Bio-sourced polyols: Castor oil-based urethanes reduce carbon footprint by 40% while maintaining 7,000 psi pressure ratings

- Recyclable composites: Gradient-structured ceramic/rubber hybrids enable 90% material recovery post-use

- Degradable additives: Starch-modified polymers decompose within 5 years in landfill conditions

Market analysis projects 25% annual growth for green piston solutions, driven by EU Taxonomy compliance requirements and operator ESG targets (2024年泥浆泵活塞杆项目可行性研究报告.docx).

Integration with Digital Drilling

AI-driven piston ecosystems will feature:

- Neural network wear prediction: Analyzing 120+ parameters (vibration spectra, thermal maps, fluid chemistry) to forecast failures with 94% accuracy

- Blockchain material tracking: Immutable records from raw material sourcing to field deployment

- Digital twin synchronization: Real-time physics-based modeling of piston-liner interactions

SPE technical papers highlight case studies where machine learning reduced unplanned downtime by 37% through adaptive lubrication algorithms (Society of Petroleum Engineers (SPE) | Oil & Gas Membership …).

These converging technologies will establish new benchmarks for drilling efficiency, with pilot projects already demonstrating 15% reduction in non-productive time during Permian Basin operations.

Conclusion and Recommendations

The seven key features of modern mud pump pistons—durable material composition, advanced structural design, high-pressure tolerance, wear resistance technology, sealing efficiency, industry standard compatibility, and smart monitoring capabilities—collectively transform drilling operations. These innovations enable:

- 40-60% reduction in downtime through extended service life and predictive maintenance (10 Essential Mud Pump Spare Parts: A Comprehensive Guide)

- 15-20% operational cost savings by minimizing unplanned replacements (2025 Mud Pump Spare Parts Guide: Top 10 Components & Industry Trends)

- 9% efficiency gains in offshore deployments through ceramic hybrid technology (Mud Pump Liner and Piston Replacement: Best Practices Guide)

Selecting the Right Piston

Use this decision matrix to match piston specifications with operational demands:

| Drilling Scenario | Fluid Type | Recommended Piston | Key Benefit |

|---|---|---|---|

| HPHT Wells (>150°C) | Oil-based/Sour Gas | HNBR/Ceramic Hybrid | 1,500+ hour lifespan in H₂S environments |

| Geothermal (>250°C) | High-Solids Slurry | Zirconia-Coated | 60% friction reduction at 300°C |

| Shale Fracking | Water-Based | Polyurethane Modular | 40% faster seal replacement |

| Deepwater Offshore | Synthetic-Based | IoT-Enabled HNBR | Real-time wear monitoring |

Critical selection factors:

- Pressure Cycles: For >7,500 psi operations, prioritize forged 35CrMo alloy cores with ±0.02mm tolerances (ISO 14693:2003(en))

- Abrasion Resistance: Ceramic coatings extend liner life 3-5x in >20% solids concentration (泥浆泵凹槽形仿生活塞寿命试验及耐磨机理分析)

- Chemical Compatibility: HNBR outperforms NBR in pH<4 or >10 environments by 200% (10 Key Facts About Mud Pump Pistons: Ultimate Guide 2025)

Partnering with Experts

For customized piston solutions tailored to specific drilling challenges, LCPumpLiner offers:

- Material Expertise: Proprietary ceramic-HNBR composites for extreme conditions

- Rapid Prototyping: 15-day lead time for non-standard piston configurations

- Lifecycle Support: Blockchain-tracked components with predictive maintenance algorithms

Key service differentiators:

- API 7K/ISO 9001 Certification: Ensures interoperability with National, Gardner Denver, and NOV pumps (Durable Mud Pump Parts Now!)

- Field-Proven Designs: 81.5% longer service life in Permian Basin trials through bionic stripe textures (Wear Performance of Bionic Dimpled‐Shape Pistons)

- Global Inventory: Same-day shipping from 15 warehouses for emergency replacements

For technical consultations or to request a customized solution, visit LCPumpLiner’s piston solutions page.

。