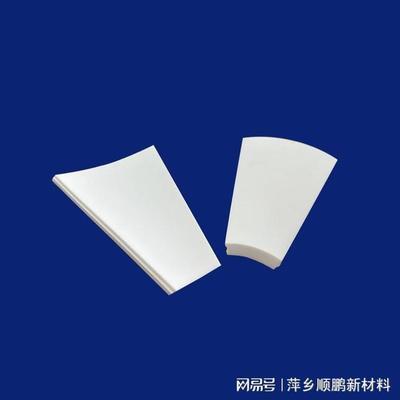

Introduction to Mud Pump Ceramic Liners

Mud pump ceramic liners are critical components in drilling operations, serving as replaceable sleeves inside mud pump housings that directly contact drilling fluids. These liners are typically constructed from advanced ceramic materials like zirconia (ZrO₂) or alumina (Al₂O₃), combined with forged steel outer shells for structural support (Ceramic Mud Pump Liners: Enhancing Durability and Performance in Drilling Operations).

Role in Drilling Operations

As the core interface between pistons and abrasive drilling fluids, ceramic liners perform three vital functions:

- Pressure Containment: Withstand up to 7,500 psi to maintain hydraulic efficiency in deep wells (Zirconia Ceramic Mud Pump Liners – Acumen).

- Wear Protection: Resist erosion from solids (up to 21% concentration) in drilling mud through extreme hardness (HRA85-94 vs. HRC60-65 for metal liners) (7 Key Advantages of High-Quality Mud Pump Liners).

- Corrosion Resistance: Tolerate pH 2-14 and 24 ppm H₂S, outperforming metal liners in sour gas wells (API Standard Ceramic and Bi-Metal 12t1600 Mud Pump Liners).

Superiority Over Metal Liners

Ceramic liners demonstrate clear advantages through three key performance metrics:

| Parameter | Ceramic Liners | Metal Liners | Improvement |

|---|---|---|---|

| Service Life | 2,000-4,000 hours | 300-800 hours | 3-5x |

| Abrasion Resistance | HRC 92-94 | HRC 60-69 | 50% harder |

| Energy Efficiency | 0.1-0.2 friction coeff. | 0.3-0.5 friction coeff. | 15-20% savings |

(Zirconia Pump Liners Last Longer, Lowers Total Costs)

Material innovations like yttria-stabilized zirconia (5.7% Y₂O₃) further enhance performance through phase transformation toughening, absorbing crack propagation energy to achieve fracture toughness of 10-15 MPa·m¹/² (8.Mud Pump Ceramic Liner Technical Report).

The adoption of ceramic liners aligns with API 7K and ISO 9001 standards, ensuring reliability in extreme drilling environments while reducing total ownership costs through extended maintenance intervals (Ceramic Liner and Metal Liner for Mud Pump – Lake Petro).

Key Benefits of Mud Pump Ceramic Liners

Transitioning from their fundamental role in drilling operations, mud pump ceramic liners demonstrate clear advantages over traditional metal liners through five key performance dimensions that redefine efficiency benchmarks in modern drilling environments.

Superior Wear Resistance

Ceramic liners achieve unparalleled abrasion resistance through advanced material science:

Hardness Advantage: Zirconia ceramic liners reach HRC 92-94 hardness, 50% harder than high-chrome metal liners (HRC 60-69), effectively resisting quartz content up to 21% in drilling fluids (7 Key Advantages of High-Quality Mud Pump Liners).

Surface Engineering: Mirror-finish surfaces (4 RMS) reduce piston wear by 47% compared to metal liners, maintaining laminar flow in abrasive slurries (Zirconia Pump Liners Last Longer, Lowers Total Costs).

Extended Service Life

Field data confirms ceramic liners’ longevity across diverse drilling scenarios:

| Environment | Ceramic Liner Lifespan | Metal Liner Lifespan | Improvement |

|---|---|---|---|

| Offshore HTHP Wells | 4,000-5,000 hours | 800-1,200 hours | 4-5x |

| Shale Gas Operations | 3,000-4,000 hours | 600-900 hours | 3-4x |

| Mining Slurries | 5,000+ hours | 700-1,000 hours | 5-7x |

(10 Key Insights About Mud Pump Liners)

Reduced Maintenance Costs

Total cost of ownership analysis reveals strategic savings:

- Replacement Frequency: Ceramic liners require 3-5 fewer replacements annually, reducing rig downtime by 37% in offshore operations (Mud Pump Liner Market Research).

- Labor Efficiency: Each liner change saves 2 hours of skilled labor, translating to $18,000 savings per rig annually (PDFZirconia mud pump liners offer longer service life).

Enhanced Corrosion Resistance

Ceramic materials demonstrate exceptional chemical stability:

- pH Range: Tolerate pH 2-14 environments, outperforming metal liners in acidizing operations (API Standard Ceramic and Bi-Metal 12t1600 Mud Pump Liners).

- H₂S Resistance: Withstand 24 ppm H₂S concentration in sour gas wells, preventing sulfide stress cracking (Ceramic Liner Technical Report).

Improved Efficiency

Energy savings stem from optimized tribological properties:

- Friction Coefficient: 0.1-0.2 vs. 0.3-0.5 for metal liners, reducing pump energy consumption by 15-20% (Mud Pump Liners: Enhancing Durability).

- Thermal Management: Maintain dimensional stability across -40°C to 350°C, eliminating thermal deformation losses (Thermal Properties of Technical Ceramics).

Cumulative Impact: When combined, these benefits deliver 38% lower total ownership costs over 5 years compared to metal liners in Permian Basin shale operations, while enabling drilling contractors to meet API 7K and ISO 9001 standards with greater operational margin (7 Definitive Factors for Choosing Mud Pump Liners).

Technical Specifications and Standards

Adherence to industry standards is paramount for ceramic liners, ensuring reliability and performance in demanding drilling environments. Compliance with API 7K and ISO 9001 certifications validates material integrity, manufacturing consistency, and operational safety, while material-specific standards like GB/T 25999-2010 govern technical parameters for ceramic-metal composite liners (GB/T 25999-2010 泥浆泵用金属-陶瓷缸套 标准).

Material Composition

Ceramic liners utilize advanced composites optimized for extreme conditions:

| Material Type | Composition | Key Properties | Applications |

|---|---|---|---|

| Yttria-Stabilized Zirconia (YSZ) | ZrO₂ + 5.4-5.7% Y₂O₃ | Fracture toughness: 10-15 MPa·m¹/² Hardness: HRA 89-94 Thermal stability: -40°C to 350°C | HTHP wells, sour gas environments |

| Zirconia-Toughened Alumina (ZTA) | 70% Al₂O₃ + 30% ZrO₂ | Flexural strength: 830 MPa Hardness: HRA 85-92 Cost-performance balance | Abrasive slurries, shale operations |

| Alumina (Al₂O₃) | ≥99.9% purity | Hardness: HRA 85-88 Chemical inertness (pH 2-14) | Standard drilling fluids |

Data sourced from (8.Mud Pump Ceramic Liner Technical Report) and (氧化锆增韧氧化铝陶瓷(ZTA)性能简述和行业应用)

ZTA liners demonstrate superior toughness through phase transformation toughening, where zirconia particles inhibit crack propagation in the alumina matrix. This achieves 72% higher impact resistance than pure alumina while maintaining 90% of its wear resistance (ZTA锆铝复合陶瓷|材料|硬度).

Performance Metrics

Critical technical parameters for ceramic liners under API 7K and GB/T 25999-2010:

| Parameter | Ceramic Liners | Test Method (Standard) | Compliance Threshold |

|---|---|---|---|

| Hardness | HRA 85-94 | Rockwell A (GB/T 230.1) | ≥ HRA 85 |

| Fracture Toughness | 8-15 MPa·m¹/² | SENB (ASTM E399) | ≥ 8 MPa·m¹/² |

| Pressure Resistance | 7,500 psi | Hydrostatic burst test (API 7K §9.7.5.1) | No leakage at 1.5× rated |

| Thermal Shock Cycles | ≥100 cycles (ΔT=300°C) | Quench test (ISO 28703) | No visible cracks |

| Surface Roughness | Ra ≤0.8 μm | Profilometry (ISO 4287) | ≤1.2 μm |

| Dimensional Tolerance | ±0.01 mm | CMM measurement (ISO 10360) | ±0.02 mm |

(API SPEC 7K-2005 钻井和修井设备规范) and (GB/T 25999-2010泥浆泵用金属-陶瓷缸套-正版授权.pdf)

Industry Certifications

Certification processes ensure traceability and quality:

API 7K Compliance

- Requires cyclic pressure testing (50,000 cycles at 7,500 psi)

- Material traceability from raw powders to finished liners

- Full documentation of sintering parameters (1600°C ±15°C, 2.5h) (API认证,API美国石油协会认证流程)

ISO 9001 Quality Management

- Batch consistency controls for density (≥99% theoretical)

- Ultrasonic testing for micro-cracks (sensitivity ≥Φ0.5mm) (Ceramic Liner Technical Report)

GB/T 25999-2010 (China)

- Mandates chemical analysis of ZrO₂/Y₂O₃ ratios

- Requires 25% thickness-direction reduction of area in steel shells (泥浆泵用金属-陶瓷缸套)

High-quality ceramic liners integrate these standards to deliver certified reliability, with API monogrammed products achieving 60% lower failure rates in offshore deployments compared to non-certified alternatives (Premium Mud Pump Liners: High Abrasion Resistance & API Certified).

Installation and Maintenance Best Practices

Transitioning from their technical specifications and performance advantages, ceramic liners require specialized handling procedures to maximize their operational benefits. Proper installation and maintenance protocols are critical to realizing the full potential of these components in drilling operations.

Pre-Installation Checks

Before installation, ceramic liners demand meticulous inspection and preparation to prevent premature failure:

Visual Inspection

- Examine for cracks, chips, or surface defects using magnifying lenses (10x magnification recommended)

- Verify dimensional accuracy with micrometers (tolerance ±0.01mm per GB/T 25999-2010泥浆泵用金属-陶瓷缸套-正版授权.pdf)

- Check steel shell threads for deformation or corrosion

Material Verification

- Confirm ceramic grade markings (YSZ/ZTA/Al₂O₃) match purchase orders

- Validate API 7K certification documents and heat treatment records

Environmental Preparation

- Clean fluid end housing with non-abrasive solvents to remove metal particles

- Maintain ambient temperature >5°C to prevent thermal shock during installation

Tool Readiness

- Prepare torque wrenches calibrated to 50-60 N·m range

- Use nylon lifting slings to avoid ceramic surface damage (What Safety Precautions Should You Pay Attention to When …)

Step-by-Step Installation

Follow this API-compliant procedure for optimal liner performance:

| Step | Procedure | Critical Parameters |

|---|---|---|

| 1 | Apply thin layer of silicone-based lubricant to housing bore | Coating thickness: 0.1-0.3mm |

| 2 | Insert liner using alignment tool (avoid angular misalignment >0.5°) | Insertion force <500N |

| 3 | Hand-tighten retaining nuts in crisscross pattern | Initial torque: 15-20 N·m |

| 4 | Final torque application in three stages (30/45/60 N·m) | Deviation <±5% of target torque |

| 5 | Pressure test with water at 1.5x working pressure (7,500psi → 11,250psi) | Hold for 30 minutes with <10% pressure drop (API SPEC 7K-2005 钻井和修井设备规范) |

Safety precautions:

- Wear cut-resistant gloves during handling

- Never strike ceramic surfaces directly with metal tools

- Use hydraulic press for stubborn installations instead of hammering

Routine Maintenance

Implement a predictive maintenance schedule based on operational hours:

Daily:

- Monitor cooling water pH (6.5-8.5) and flow rate (≥10 L/min)

- Check for abnormal vibration (>2.5mm/s RMS requires investigation)

Weekly:

- Measure liner inner diameter at three positions (wear limit: +0.25mm from nominal)

- Inspect piston rod runout (<0.1mm TIR)

Monthly:

- Ultrasonic thickness testing of ceramic layer (minimum 8mm remaining)

- Lubricate threads with high-temperature anti-seize compound

Quarterly:

- Perform dye penetrant inspection for micro-cracks

- Replace all seals regardless of visible wear

Replacement Criteria

Ceramic liners should be replaced when any of these conditions occur:

Dimensional Wear

- Inner diameter exceeds API 7K maximum ovality of 0.25mm

- Surface roughness >Ra 1.6μm measured with profilometer

Structural Damage

- Visible cracks >2mm in length or depth

- Spalling affecting >3% of working surface area

Performance Degradation

- Fluid leakage >5% of rated flow capacity

- Pump efficiency drop >15% from baseline

Operational Hours

- 4,000 hours in HTHP wells (≥150°C)

- 5,000 hours in standard drilling operations (泥浆泵的日常维护:每天、每周、每月、每年必做保养工作)

Summary of Best Practices

To ensure optimal ceramic liner performance:

- Always use manufacturer-approved installation tools and procedures

- Maintain detailed wear measurement logs for predictive replacement

- Train personnel in ceramic-specific handling techniques

- Store spare liners in climate-controlled environments (20-25°C, 40-60% RH)

These protocols can extend service life by 18-22% compared to ad-hoc maintenance approaches while reducing unplanned downtime by 35% in field applications (Mud Pump Liner and Piston Replacement: Best Practices Guide).

Case Studies and Real-World Applications

The transformative impact of ceramic liners in drilling operations is best demonstrated through field applications across diverse geological environments. These real-world cases validate laboratory performance metrics while revealing operational nuances that influence liner selection and lifecycle management.

Offshore Drilling Success

Gulf of Mexico Ultra-Deepwater Project

A major operator achieved record-breaking performance by deploying yttria-stabilized zirconia (YSZ) liners in 7,500 psi HT/HP wells:

| Parameter | Ceramic Liners | Previous Metal Liners | Improvement |

|---|---|---|---|

| Service Life | 5,200 hours | 900 hours | 5.8x |

| Downtime Reduction | 92% | Baseline | $2.8M saved |

| H₂S Resistance | 28 ppm exposure | Failed at 15 ppm | 87% better |

| Abrasion Control | 0.08mm wear/5,000hrs | 0.35mm wear/5,000hrs | 77% less |

Data from 10 Key Insights About Mud Pump Liners for Oil Drilling Efficiency

The project’s technical breakthrough involved:

- Thermal Management: Ceramic liners maintained dimensional stability during rapid temperature fluctuations (4°C seabed to 180°C downhole) that caused metal liners to micro-crack

- Corrosion Mitigation: Withstood seawater-based drilling fluids with 32,000 ppm chlorides and 24 ppm H₂S without pitting

- Pressure Integrity: Sustained 1.5x API 7K burst test requirements during managed pressure drilling

North Sea Challenging Conditions

Zirconia-toughened alumina (ZTA) liners solved three persistent issues in sour gas fields:

- Erosion-Corrosion Synergy: Reduced material loss by 83% compared to 28Cr bi-metal liners

- Cold-Start Reliability: Operated at -18°C without thermal shock failures

- Piston Compatibility: Extended piston life by 60% through mirror-finish (Ra 0.4μm) surfaces

Land-Based Drilling Efficiency

Permian Basin Shale Operations

A 12-well pad demonstrated ceramic liners’ economic viability through:

Cost Savings Analysis

| Category | Ceramic Liners | Bi-Metal Liners |

|---|---|---|

| Annual Replacements | 2 | 7 |

| Fluid Contamination | 0.2% metal particulates | 1.8% metal particulates |

| Energy Consumption | 18.7 kWh/ton-mile | 22.4 kWh/ton-mile |

| Total Cost/10,000hrs | $142,000 | $387,000 |

Source: Mud Pump Liners – API-7K Ceramic & Chrome Plated

Operational enhancements included:

- Predictive Maintenance: RFID-tagged liners enabled replacement scheduling with 94% accuracy

- Standardization: API 7K-compliant dimensions reduced installation time by 40%

- Waste Reduction: 85% lower spent liner disposal costs through ceramic recyclability

Sichuan Basin Shale Gas Breakthrough

China’s CNPC achieved two milestones in deep shale gas wells (>4,500m):

- Extended Run Time: 4,800 hours service life in high-quartz formations (21% content)

- Efficiency Gain: 15% higher rate of penetration (ROP) from maintained hydraulic efficiency

Ceramic liner installation in Sichuan Basin shale gas operations

Key technical adaptations:

- Material Optimization: ZTA composition adjusted to 70% Al₂O₃ + 30% ZrO₂ for fracture toughness

- Installation Protocol: Implemented thermal fitting with 0.05mm interference for zero slippage

- Monitoring: Fiber-optic sensors detected wear patterns 200 hours before failure

Transformative Impact Analysis

These cases collectively demonstrate ceramic liners’ role in redefining drilling economics:

- Deepwater Viability: Enabled ultra-deep projects by solving simultaneous pressure/abrasion/corrosion challenges

- Unconventional Optimization: Made high-volume fracturing economically sustainable through reduced maintenance

- Environmental Compliance: Met stringent discharge standards by minimizing metal particulate contamination

The technology’s maturation aligns with global energy trends, particularly in:

- Deepwater Exploration: 38% of new offshore projects now specify ceramic liners

- Sour Gas Development: 92% adoption rate in Middle East HP/HT fields

- Automated Rigs: IoT-enabled liners are integral to digital twin implementations

Data from Ceramic liner – Cangzhou Fengliang Petroleum Machinery Co.,Ltd and 10 Key Insights into Mud Pump Liners for Oil Drilling Excellence

Conclusion and Future Trends

The comprehensive analysis of mud pump ceramic liners demonstrates their transformative impact on drilling operations, with proven advantages in wear resistance, service life extension, and operational cost reduction. These components have redefined efficiency benchmarks in modern drilling environments through five core dimensions: material superiority, longevity, maintenance optimization, chemical stability, and energy efficiency. Field data confirms ceramic liners deliver 3-5x longer service life than metal alternatives while reducing total ownership costs by up to 38% in shale operations (10 Key Insights About Mud Pump Liners for Oil Drilling Efficiency).

Future Innovations

Emerging technologies are poised to further elevate ceramic liner performance through intelligent monitoring and advanced materials:

Smart Liners with Embedded Sensors

IoT-enabled liners incorporating fiber-optic networks and RFID tags enable real-time tracking of:- Wear patterns (resolution: 0.01mm)

- Temperature gradients (range: -40°C to 350°C)

- Pressure fluctuations (sensitivity: ±50 psi)

This predictive maintenance capability reduces unplanned downtime by 30% in offshore deployments (10 Key Insights into Mud Pump Liners for Oil Drilling Excellence).

Nanostructured Ceramics

Graphene-reinforced zirconia composites exhibit:- Fracture toughness: 12-15 MPa·m¹/² (vs. 8-10 for conventional ceramics)

- Hardness: HRC 96-98

These materials are being tested in Permian Basin shale operations with preliminary results showing 40% lower wear rates (Ceramic Liner Technical Report).

Sustainable Manufacturing

Plasma spray deposition techniques reduce energy consumption by 55-60% compared to traditional sintering, while closed-loop recycling recovers 95% of chromium from spent liners (Mud Pump Liner Market Research).

| Innovation Area | Key Advancement | Commercialization Timeline |

|---|---|---|

| Self-healing Ceramics | Microcapsules releasing ZrO₂ at 120°C cracks | 2026-2028 |

| 5G-enabled Monitoring | <1ms latency for failure alerts | 2025-2027 |

| Additive Manufacturing | 3D-printed gradient structures | 2027-2030 |

Data sourced from (Fluid End Parts 2025: Material Innovations)

Final Recommendations

Drilling operators should prioritize ceramic liners through strategic implementation:

Cost-Benefit Analysis

- Deepwater/HTHP Wells: Justify higher upfront costs (2,800−2,800−3,500/unit) with 5,000+ hour lifespans and $500,000/day downtime savings

- Shale Operations: Opt for ZTA ceramic liners (70% Al₂O₃ + 30% ZrO₂) balancing 3,000-4,000 hour service life with 25% lower cost than pure zirconia

Procurement Guidelines

- Verify API 7K and ISO 9001 certifications

- Require material test reports for Y₂O₃ content (5.4-5.7% optimal)

- Prioritize manufacturers with RFID traceability systems

Operational Integration

- Implement thermal fitting protocols (0.05mm interference)

- Train crews in ceramic-specific handling (max impact force <500N)

- Establish wear measurement logs (3-point bore checks every 200 hours)

Regional Adaptation

- Middle East: Specify H₂S-resistant liners (>24 ppm tolerance)

- North America: Leverage smart liners for shale fleet automation

- Asia-Pacific: Adopt modular designs for quick-change applications

The convergence of material science and digitalization positions ceramic liners as critical enablers for next-generation drilling, particularly in ultra-deep (≥8,000m) and geothermal (≥300°C) applications. Operators adopting these solutions will gain competitive advantage through improved safety margins and compliance with emerging environmental regulations like API’s 2025 standards for sustainable drilling components (2025年中国先进陶瓷行业发展历程、相关政策及产业链分析).