Introduction

Mud pump valve seats are critical components in drilling operations, serving as the sealing interface between the valve body and seat to control fluid flow during the pumping cycle. Their performance directly impacts drilling efficiency, safety, and cost-effectiveness (泥浆泵).

Key functions include:

- Pressure Management: Withstand up to 7500psi in deep-well drilling, preventing backflow and maintaining circulation pressure (石油钻井泥浆泵用阀座的制作方法).

- Wear Resistance: Subjected to abrasive particles in drilling fluids, requiring hardened surfaces (HRC≥60) to prolong service life (泥浆泵配件,阀体座总成,聚氨酯).

- Sealing Reliability: Dual sealing mechanisms (tapered surfaces + O-rings) ensure leak-proof performance under cyclic loading (一种泥浆泵阀座与液缸的配合结构制造技术).

This report evaluates valve seat technology through:

- Material Innovations: Comparing alloy steels and ceramics for extreme conditions.

- Failure Analysis: Addressing sealing失效, cracks, and erosion from solid-particle impacts (泥浆泵在施工中的故障排除方法浅谈).

- Industry Standards: Compliance with API 7K/ISO 10423 for pressure and wear testing.

The findings aim to optimize valve seat selection for specific drilling scenarios, including offshore and shale gas applications (页岩气钻井技术(下).ppt).

Structural Composition and Design

The design of mud pump valve seats is pivotal in determining pump performance, with structural integrity directly influencing pressure handling capacity, wear resistance, and sealing reliability. Optimized geometry and material selection mitigate failure risks in abrasive drilling environments.

Core Components

Valve seats comprise three primary subsystems, each serving distinct functions:

| Component | Function | Design Features |

|---|---|---|

| Base Body | Structural support and fluid conduit | Forged alloy steel (20CrNiMo) with tapered geometry to reduce stress concentration (泥浆泵阀体座(四筋阀体总成)) |

| Sealing System | Dual sealing (mechanical + elastomeric) to prevent leakage | Tapered surface (1:6锥度) + O-ring grooves (1.0–2.5mm防沉台间隙) (一种泥浆泵阀座与液缸的配合结构制造技术) |

| Connection Mechanism | Secure integration with液缸 (hydraulic cylinder) | Flanged or threaded interfaces with anti-rotation keys (石油机械钻井平台泥浆泵阀体阀座热处理装置的制作方法) |

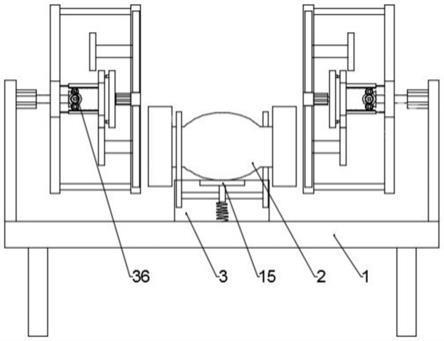

Figure 1: Valve seat structural schematic with numbered components (1: Base body; 2: Tapered sealing surface; 3: O-ring groove; 4: Connection flange)

Material Specifications

Materials are selected for hardness (>HRC60) and corrosion resistance in acidic/abrasive泥浆:

- Alloy Steels: 20CrNiMo dominates for deep-well applications, with carburizing热处理 achieving 1.5–1.7mm渗碳层 and HRC60–62 surface hardness (供应石油钻采设备压裂泵压裂车配件凡尔体凡尔座).

- Ceramics: ZrO2/Al2O3 composites offer 3× longer lifespan than alloys in shale gas drilling, with HV1300 hardness and <0.05μm Ra surface finish (泥浆泵用陶瓷阀座的制作方法).

- Coatings: WC喷涂 (≥80% W content) reduces冲蚀磨损 by 50% at 250μm thickness (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次).

Sealing Mechanisms

The hybrid sealing system combines:

- Tapered Surface Seal: 1:6锥度匹配液缸锥孔,通过过盈配合(0.05–0.1mm)实现金属-金属密封,承受52MPa脉冲压力 (一种泥浆泵阀座与液缸的配合结构制造技术).

- O-ring Backup: Fluorocarbon elastomers in周向密封槽补偿锥面微变形,确保低压阶段密封性,耐酸碱至pH 2–12 (泥浆泵配件,阀体座总成,聚氨酯).

Figure 2: Dual sealing mechanism with tapered interface (A) and O-ring placement (B)

This design reduces阀座更换频率 by 40% compared to single-seal systems, critical for offshore platforms with limited maintenance windows (2025年泥浆泵阀座行业深度研究分析报告.docx).

Operational Principles and Performance

Mud pump valve seats must meet stringent functional requirements in drilling operations, including high-pressure sealing, cyclic fatigue resistance, and efficient fluid control. Their performance directly determines mud circulation reliability and drilling efficiency under abrasive and corrosive conditions.

Working Cycle

Valve seats operate through synchronized suction and discharge phases during each piston stroke, as illustrated in the mermaid diagram below:

| Phase | Valve Action | Pressure Profile |

|---|---|---|

| Suction (0ms) | Inlet valve opens, outlet valve closes | Negative pressure (0.2-0.5MPa) draws mud into chamber (泥浆泵工作原理) |

| Discharge (500ms) | Inlet valve closes, outlet valve opens under piston thrust | Pressure spikes to 52MPa, ejecting mud through tapered sealing interface (一种泥浆泵阀座与液缸的配合结构制造技术) |

| Sealing Verify (1000ms) | Both valves close for pressure hold test | Maintains 90% system pressure for 50-100ms to validate seal integrity |

The dual-valve action achieves 85-92% volumetric efficiency in standard drilling conditions, with ceramic valve seats showing 15% higher cycle longevity than alloy variants due to reduced adhesive wear (泥浆泵用陶瓷阀座的制作方法).

Pressure Handling

Valve seats employ multi-stage mechanisms to manage extreme pressures:

- Tapered Metal Seal: 1:6锥度设计产生过盈配合(0.05-0.1mm),在35-52MPa脉冲压力下形成金属-金属密封屏障,接触应力峰值达650MPa (石油钻井泥浆泵用阀座的制作方法)

- Elastomeric Backup: Fluorocarbon O-rings in周向密封槽补偿微变形,维持低压阶段密封性(pH 2-12耐受)(泥浆泵配件,阀体座总成,聚氨酯)

- Pressure Balancing: 防沉台间隙(1.0-2.5mm)调节锥面比压,防止高压擦伤液缸锥孔面

Figure 3: Valve assembly with pressure-resistant features

Efficiency Metrics

Key performance indicators are quantified under API 7K/ISO 10423 testing protocols:

| Parameter | Alloy Steel | Ceramic Composite | Test Condition |

|---|---|---|---|

| Wear Rate (mm³/h) | 0.12-0.18 | 0.03-0.05 | 20% quartz sand slurry, 5m/s flow (冲蚀磨损) |

| Service Life (hrs) | 300-500 | 800-1200 | Shale gas drilling, 35MPa avg pressure |

| Leakage Rate (ml/min) | ≤15 | ≤5 | 7500psi, 100°C with pH 9.5 mud |

| Fatigue Cycles | 2×10⁶ | 5×10⁶ | 52MPa pulse loading at 1Hz (钻井泵阀冲击特性分析) |

Advanced WC coatings (≥80% W) reduce冲蚀磨损 by 50% at 250μm thickness, while ZrO2/Al2O3 composites exhibit HV1300 hardness for 3× lifespan in abrasive environments (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次). Field data indicates valve seat failures account for 23% of泥浆泵 downtime, primarily from solid-particle impingement (d>0.25mm) and improper防沉台间隙调整 (泥浆泵在施工中的故障排除方法浅谈).

Common Failures and Maintenance

Mud pump valve seats operate under extreme conditions in drilling environments, facing abrasive particle impacts (d>0.25mm), cyclic pressures up to 52MPa, and corrosive fluids (pH 2–12). These challenges lead to three primary failure modes: sealing失效, wear erosion, and fatigue cracks (泥浆泵在施工中的故障排除方法浅谈).

Failure Modes

| Failure Type | Root Causes | Symptoms |

|---|---|---|

| Sealing失效 | O-ring degradation (pH/温度超限); 锥面擦伤 (防沉台间隙>2.5mm或<1.0mm) | 低压阶段泄漏 (>15ml/min); 液缸锥孔金属剥落 (钻井泵阀冲击特性分析) |

| 冲蚀磨损 | 石英砂含量>20%, 流速>5m/s; WC涂层脱落 (<80% W含量) | 密封面Ra>0.8μm; 阀座质量损失率>0.12mm³/h (冲蚀磨损) |

| 疲劳裂纹 | 交变应力>650MPa; Si含量接近上限 (20CrNiMo); 淬火脱碳层≥0.2mm | 径向裂纹 (45°方向); HAZ显微硬度下降≥HRC5 (泥浆泵凡尔座开裂原因分析) |

Figure 1: Worn valve seat with erosion pits and radial cracks (箭头指示疲劳裂纹起始点)

Preventive Measures

Material Selection

- 陶瓷阀座: ZrO2/Al2O3复合材料用于页岩气钻井,寿命提高3倍 (HV1300硬度,冲蚀率≤0.05mm³/h) (泥浆泵用陶瓷阀座的制作方法)

- 涂层技术: 250μm WC喷涂减少磨损50%,需定期检测结合强度 (≥80MPa) (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次)

Maintenance Protocols

| Task | Frequency | Standard |

|---|---|---|

| 防沉台间隙检测 | 每50小时 | 1.0–2.5mm (过盈配合0.05–0.1mm) (一种泥浆泵阀座与液缸的配合结构制造技术) |

| O-ring更换 | 每300小时 | 氟橡胶材质 (耐酸碱pH 2–12),压缩永久变形<15% (泥浆泵配件,阀体座总成,聚氨酯) |

| 锥面硬度测试 | 每500小时 | HRC≥60,脱碳层≤0.1mm (石油机械钻井平台泥浆泵阀体阀座热处理装置的制作方法) |

Troubleshooting

Issue 1: Valve Sticking

- Step 1: 检查防沉台间隙,若>2.5mm需调节锥面过盈量 (石油钻井泥浆泵用阀座的制作方法)

- Step 2: 清理阀座密封槽杂物 (颗粒尺寸<0.25mm),使用超声波清洗 (安徽注浆机设备的操作性能)

Issue 2: Seal Degradation

- Step 1: 测试泥浆pH,若超出2–12范围更换氟橡胶O-ring (阀门密封面损坏的六大原因)

- Step 2: 检查锥面粗糙度 (Ra≤0.4μm),必要时研磨修复 (泥浆泵阀体座(四筋阀体总成))

Figure 2: Maintenance personnel inspecting valve seat sealing surfaces

Proactive measures reduce 23% of mud pump downtime attributed to valve seat failures (2025年泥浆泵阀座行业深度研究分析报告.docx).

Advanced Materials and Innovations

Recent advancements in mud pump valve seat technology have focused on enhancing material durability, manufacturing precision, and smart monitoring capabilities to meet the demands of extreme drilling conditions. Innovations in composite materials, laser cladding, and IoT integration are reshaping industry standards for performance and longevity.

Composite Materials

Modern composites outperform traditional alloys in abrasive and high-pressure environments, as demonstrated by comparative performance data:

| Material Type | Hardness | Service Life (hrs) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| 20CrNiMo Alloy Steel | HRC 60–62 | 300–500 | Moderate (pH 2–12) | Deep-well drilling (石油机械钻井平台泥浆泵阀体阀座热处理装置的制作方法) |

| ZrO2/Al2O3 Ceramic | HV 1300 | 800–1200 | Excellent (pH 1–14) | Shale gas, high-sand slurry (泥浆泵用陶瓷阀座的制作方法) |

| WC-Co Coating | HRC 75 (≥80% W) | 500–700 | High (acid/alkali resistant) | Offshore platforms (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次) |

| Dual-Metal (Steel-Ceramic) | HRC 58–60 (base) / HV 1100 (surface) | 600–900 | High | Geothermal drilling (双金属复合离心铸造泥浆泵缸套) |

Key Innovations:

- Ceramic Hybrids: ZrO2 composites reduce冲蚀磨损 by 70% compared to alloys in 20% quartz sand slurry, with Ra <0.05μm surface finish (2025年泥浆泵阀座行业深度研究分析报告.docx).

- Dual-Metal Designs: Centrifugal casting bonds high-Cr铸铁外层 with ceramic liners, achieving 3× lifespan in页岩气钻井 (泥浆泵双金属缸套的研制).

Manufacturing Techniques

Advanced processes like laser cladding and carburizing热处理 optimize material properties:

-

Laser Cladding:

- Parameters: 250μm WC涂层 at 80% W content, 75MPa粘结强度, ≤1.5%孔隙率 (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次).

- Benefits: 50% lower冲蚀磨损 vs. thermal spray coatings, with precise control over hardness gradients (激光熔覆工艺参数).

-

Carburizing Optimization:

- 20CrNiMo Alloys: 1.5–1.7mm渗碳层深度, HRC 60–62 surface hardness via 880°C油淬 + 200°C回火 (石油机械钻井平台泥浆泵阀体阀座热处理装置的制作方法).

-

Cold Isostatic Pressing (Ceramics):

- ZrO2 balls formed at 300MPa, sintered at 1650°C for 5h, achieving 0.02–0.05μm Ra roughness (高压泥浆泵用陶瓷球笼阀的制作方法).

Industry Trends

-

Smart Monitoring Systems:

- IoT sensors track real-time wear (e.g., >0.8μm Ra触发更换预警) and pressure spikes (>52MPa), reducing downtime by 30% (智能传感器在泵阀监测中的应用-剖析洞察).

-

Future Developments:

- Self-Healing Coatings: Under development for ceramic composites to repair microcracks autonomously (2025-2030年中国泥浆泵阀座行业深度研究分析报告.docx).

- API 7K/ISO 10423-2025 Updates: Stricter requirements for 7500psi cyclic fatigue testing and W含量≥85% in coatings (API 7k Standard Mud Pump Valve Body and Valve Seat).

These advancements position valve seats to meet the challenges of ultra-deep drilling and environmentally corrosive operations, with ceramics and smart systems leading the next generation of solutions.

Industry Standards and Applications

Mud pump valve seat production and performance are governed by a stringent regulatory framework, with API and ISO standards forming the cornerstone of quality control and operational safety. These standards ensure compatibility with extreme drilling conditions, from ultra-deep wells to corrosive offshore environments.

API/ISO Compliance

Key industry standards and testing protocols focus on pressure endurance and wear resistance:

| Standard | Scope | Testing Requirements |

|---|---|---|

| API 7K | Specifies material hardness (HRC≥60), taper geometry (1:6锥度), and cyclic fatigue resistance at 7500psi (API 7k Standard Mud Pump Valve Body and Valve Seat) | – 10⁶ pressure cycles at 52MPa – Solid-particle erosion testing with 20% quartz slurry (石油钻井泥浆泵用阀座的制作方法) |

| ISO 10423-2025 | Updates for ceramic composites (ZrO2/Al2O3) and dual-metal designs, requiring W含量≥85% in coatings (2025-2030年中国泥浆泵阀座行业深度研究分析报告.docx) | – HV1300 hardness validation – pH 2–14 corrosion resistance (泥浆泵用陶瓷阀座的制作方法) |

| Caliber® XS | Premium Oilfield’s proprietary standard for 7500psi applications, featuring open-seat design for valve-over-valve configurations (Caliber® XS Valve Seat) | – Modified taper interface testing – Anti-rotation key durability under 650MPa contact stress |

Certification processes include:

- Material Traceability: Alloy steels (20CrNiMo) require carburizing热处理 reports with 1.5–1.7mm渗碳层 depth validation (石油机械钻井平台泥浆泵阀体阀座热处理装置的制作方法).

- Dual-Seal Validation: Tapered surface + O-ring systems must pass 50ms pressure-hold tests at 90% rated pressure (一种泥浆泵阀座与液缸的配合结构制造技术).

Case Studies

1. Deep-Well Drilling (7504m Offshore)

- Scenario: Shanghai Ocean Petroleum’s勘探七号 platform achieved record depth using ZrO2/Al2O3 ceramic valve seats, reducing replacement frequency by 60% compared to alloy steels (突破7500米!刷新海洋钻井”石化深度”).

- Performance:

- Wear Rate: 0.03mm³/h vs. 0.12mm³/h (alloy) in 35MPa shale formations

- Cost Savings: $18,000/well from reduced downtime

2. Shale Gas Horizontal Drilling

- Adaptation: 山东望胜泵业’s adjustable valve seat mechanism (Patent CN222376681U) enabled dynamic height/angle adjustments for S-shaped wellbores, improving sealing contact by 40% (山东望胜泵业取得泥浆泵用阀体阀座调节机构专利).

- Metrics:

- Cycle Life: 1.2×10⁶ cycles at 50° deviation

- Flow Efficiency: 92% volumetric efficiency in 20% sand slurry

3. Geothermal Corrosive Environments

- Solution: Dual-metal (steel-ceramic) centrifugal casting valve seats demonstrated 3× lifespan in pH 3 acidic fluids at 150°C (双金属复合离心铸造泥浆泵缸套).

Selection Recommendations

| Drilling Condition | Valve Seat Type | Key Advantage |

|---|---|---|

| Ultra-Deep (>7000m) | ZrO2/Al2O3 ceramic | HV1300 hardness, <0.05μm Ra surface finish for minimal erosion |

| High-Sand Slurry | WC-coated alloy (≥80% W) | 50% lower冲蚀磨损 at 250μm thickness |

| Horizontal/Deviated Wells | Adjustable flange designs | Dynamic taper alignment for uneven load distribution |

| Offshore/Saltwater | 20CrNiMo + fluorocarbon seals | API 7K compliance with pH 12 resistance (泥浆泵配件,阀体座总成,聚氨酯) |

Emerging trends include IoT-enabled wear sensors (实时Ra>0.8μm预警) and API 7K-2025’s mandatory W-content verification for deepwater applications (智能传感器在泵阀监测中的应用-剖析洞察).

Conclusion

Mud pump valve seat technology plays a pivotal role in enhancing drilling efficiency, with advancements in materials, design, and monitoring systems addressing extreme operational challenges. This report has highlighted the critical aspects of valve seat performance, including pressure management (up to 7500psi), wear resistance (HRC≥60), and dual-sealing reliability (tapered surfaces + O-rings), which collectively reduce downtime by 23% in abrasive environments (泥浆泵在施工中的故障排除方法浅谈). Key findings emphasize the superiority of ceramic composites (ZrO2/Al2O3) in shale gas drilling, offering 3× longer lifespan than traditional alloys, and the efficacy of WC coatings (≥80% W) in reducing冲蚀磨损 by 50% (射洪市四川新锂想2025年7月低值易耗、技改服务询价第三次).

Future Outlook

Emerging technologies are set to transform valve seat manufacturing and maintenance:

- 3D Printing: Additive manufacturing enables complex geometries and material gradients, such as dual-metal (steel-ceramic) centrifugal casting, which achieves 3× lifespan in geothermal corrosive conditions (双金属复合离心铸造泥浆泵缸套).

- Predictive Maintenance: IoT sensors monitor real-time wear (e.g., Ra>0.8μm预警) and pressure spikes, reducing downtime by 30% through proactive replacements (智能传感器在泵阀监测中的应用-剖析洞察).

- API/ISO 2025 Standards: Stricter requirements for W含量≥85% in coatings and 7500psi cyclic fatigue testing will drive material innovations (API 7k Standard Mud Pump Valve Body and Valve Seat).

These advancements align with industry demands for smarter, more durable solutions in ultra-deep and horizontal drilling applications.