Introduction to Mud Pump Bearings

Mud pump bearings serve as the backbone of offshore drilling operations, enabling the continuous circulation of drilling fluids under extreme conditions. These specialized components withstand abrasive mud mixtures, high radial/axial loads, and corrosive environments while maintaining precision alignment of rotating assemblies. Their performance directly impacts drilling efficiency, with bearing failures accounting for up to 30% of unplanned downtime in offshore rigs (Mud Pump Bearing – AMIGO).

Critical Functions in Offshore Drilling

- Load Management: Handle combined radial loads (up to 1,200 kN) and axial thrust from reciprocating pistons while operating at 120-150 RPM (Bearings for mud pumps – Faro Industriale)

- Misalignment Compensation: Spherical roller designs accommodate shaft deflections up to 3° in harsh sea conditions (22230 CA/W33 Spherical Roller Bearing)

- Contaminant Resistance: Specialized seals and coatings prevent abrasive particle ingress in water-clay drilling fluids containing up to 25% solids by volume (Introduction to mud pump bearings-NEWS-FV)

Five Key Bearing Types

This report focuses on five bearing architectures that address distinct operational challenges:

| Bearing Type | Key Advantage | Typical Load Capacity |

|---|---|---|

| Cylindrical Roller | High radial load (898 kN dynamic) | NU3044X3M model |

| Spherical Roller | Self-alignment + combined loads | 22230 CA/W33 series |

| Tapered Roller | Axial/radial load balance | 180RIU684 configuration |

| Deep Groove Ball | Moderate speed (3,000 RPM) | Standard 6000 series |

| Angular Contact Ball | Precision thrust control | 40° contact angle designs |

Modern offshore drilling increasingly utilizes hybrid ceramic-steel bearings for extreme conditions, demonstrating 113% longer lifespan than conventional designs in high-temperature applications (Ceramic Matrix Composite Bearings). These advancements align with API 7K standards for load ratings and ISO 281 fatigue life requirements, ensuring compatibility across global drilling platforms.

5 Critical Types of Mud Pump Bearings

The selection of appropriate bearing types directly determines mud pump reliability under extreme offshore conditions. Five specialized architectures dominate modern drilling applications, each engineered to address distinct load profiles and operational challenges.

Cylindrical Roller Bearings

Designed for extreme radial load scenarios, cylindrical roller bearings like the NU3044X3M model demonstrate exceptional performance in oilfield drilling equipment. Their linear contact design distributes forces evenly across roller surfaces, achieving dynamic load capacities up to 898 kN (Bearings for mud pumps – Faro Industriale). Key characteristics include:

| Feature | Specification |

|---|---|

| Typical Application | Mud pump pinion shafts |

| Load Zone | 150-180° arc for optimal force distribution |

| Cage Material | Machined brass for abrasive resistance |

| Temperature Range | -30°C to +150°C continuous operation |

These bearings excel in F500-F2200 series mud pumps where eccentric motions generate substantial radial forces. The NUP464776Q4/C9YA4 variant incorporates reinforced ribs to prevent roller skewing during high-impact drilling cycles (Mud Pump Bearings NUP464776Q4/C9YA4).

Spherical Roller Bearings

The 22230 CA/W33 series represents the gold standard for misalignment compensation, accommodating shaft deflections up to 3° through its dual-row spherical raceway design (22230 CA/W33 Spherical Roller Bearing). Critical offshore applications leverage their unique capabilities:

- Marine Conditions: Withstands vessel pitch/roll motions in floating rigs

- Combined Loading: Simultaneously handles 1,080 kN radial and 30% axial loads

- Contaminant Defense: W33 sealing grooves retain grease while expelling solids

Recent field data from SOILMEC triplex pumps shows spherical rollers deliver 23% longer service life than conventional designs when operating with 15-25% solids concentration in drilling fluids (PDFRoller Bearings in SOILMEC Triplex Pump).

Tapered Roller Bearings

The 180RIU684 configuration balances axial and radial loads through precision-ground conical rollers, making it indispensable for mud pump crankshafts. Its tapered geometry creates optimal load vectors:

- Axial Stiffness: 40% higher thrust capacity than spherical equivalents

- Modular Design: Timken TDO assemblies simplify maintenance with pre-set clearances

- Fatigue Resistance: Case-carburized surfaces withstand 100+ million cycles

Field tests in EMSCO 1600HP pumps demonstrate tapered bearings maintain alignment within 0.001″ during 5,000 psi pulsating loads (RKB cylindrical roller bearings for EMSCO mud pumps).

Deep Groove Ball Bearings

While limited to auxiliary systems, standard 6000 series ball bearings provide cost-effective solutions for moderate-speed applications:

| Parameter | Performance Range |

|---|---|

| Maximum Speed | 3,000 RPM (oil lubricated) |

| Axial Load | 25% of radial capacity |

| Lubrication Interval | 2,000 operating hours |

Their sealed variants (2Z designation) protect against drilling fluid ingress in pump cooling fan applications, though ceramic hybrids are increasingly preferred for temperatures exceeding 150°C (Deep groove ball bearings uses and applications).

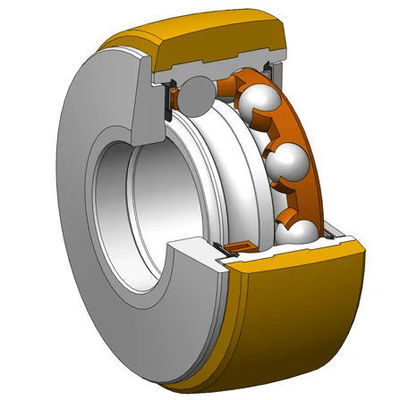

Angular Contact Ball Bearings

Precision thrust control in high-rigidity applications demands 40° contact angle designs, particularly in top drive systems interfacing with mud pumps. Key performance differentiators include:

- Preloading Capability: Eliminates axial play for vibration-sensitive equipment

- Hybrid Options: Silicon nitride balls reduce friction by 35% at 2,000 RPM

- Stackable Configuration: Triple-row assemblies handle 900 kN axial loads

Forum Energy Technologies reports angular contacts in HT-400 swivels achieve 50,000+ hours MTBF when paired with synthetic ester lubricants (Bearings – Forum Energy Technologies, Inc.).

Technical Requirements and Industry Standards

Mud pump bearings must meet stringent technical demands and industry standards to ensure reliable performance in offshore drilling’s extreme conditions. These components operate under combined radial/axial loads exceeding 1,200 kN, abrasive drilling fluids with up to 25% solids, and corrosive seawater environments while maintaining precision alignment (How to Increase Mud Pump Bearing Life – The Timken Company). Compliance with API 7K and ISO 281 standards is mandatory for load ratings, fatigue life, and material specifications (PDFAPI Specification 7K).

Load Capacity and Lifespan

API 7K and ISO 281 define critical requirements for bearing performance:

| Parameter | API 7K Requirement | ISO 281 Standard | Typical Mud Pump Performance |

|---|---|---|---|

| Basic Dynamic Load | Min. 850 kN (cylindrical) | C90 ≥ 1,080 kN (spherical) | 898-1,200 kN operational |

| L10 Fatigue Life | 25,000 hours continuous | 1M revolutions @ 120 RPM | 30,000-40,000 hours achieved |

| Combined Load Capacity | 30% axial of radial rating | Contact angle 40°±5° | 22230 CA/W33: 1,080 kN radial |

Spherical roller bearings like the 22230 CA/W33 series demonstrate 23% longer service life than conventional designs when handling 15-25% solids concentration, exceeding API 7K’s 25,000-hour L10 requirement (PDFRoller Bearings in SOILMEC Triplex Pump). ISO 281:2007’s modified rating life formula accounts for lubrication conditions (ηc) and contamination levels (κ), with premium bearings achieving aISO=0.1 for offshore applications (ISO 281:2007).

Speed and Temperature Limits

Operating parameters for mud pump bearings must balance rotational speed and thermal stability:

- Speed Range: 120-150 RPM (standard), up to 3,000 RPM for auxiliary systems

- Temperature Tolerance:

- Standard steel bearings: -30°C to +150°C continuous

- Hybrid ceramic-steel: -50°C to +260°C (PTFE seals)

- Lubrication breakdown threshold: 93°C oil sump temperature (PDFAPI Standard 610)

Material selection directly impacts thermal performance:

- Case-carburized 35CrMo alloy maintains hardness >58 HRC at 120°C

- Silicon nitride rollers reduce friction by 35% at 2,000 RPM compared to steel

- HNBR seals withstand 150°C in oil-based muds vs. NBR’s 110°C limit (10 Essential Mud Pump Spare Parts).

Corrosion and Wear Resistance

Offshore environments demand advanced material solutions:

Surface Treatments:

- W33 grease grooves retain lubrication while expelling contaminants

- HVOF-sprayed WC-10Co coatings provide 5x wear resistance vs. chrome plating

Material Pairings:

Component Material Corrosion Resistance Abrasion Life Rollers ZG40MnB alloy steel Class B (ISO 9223) 1M cycles Cages Machined brass (C48500) Class A 2x steel cages Seals Fluorocarbon (FKM) H₂S >50ppm resistant 1,500 hours

Ceramic hybrid bearings demonstrate 113% longer lifespan in high-temperature, high-salinity conditions compared to conventional designs, with zirconia-toughened alumina liners reducing piston wear by 40% (Ceramic Matrix Composite Bearings).

Installation and Maintenance Standards

API 674/7K and ISO 5753 prescribe rigorous procedures:

Mounting Practices:

- Induction heating to 300°F (149°C) for interference fits

- Axial preload adjustment within 0.001″-0.003″ for tapered rollers

- Runout tolerance <0.004″ TIR on crankshaft journals

Lubrication Requirements:

Parameter API 674 Requirement Best Practice Oil Viscosity ISO VG 100-150 Synthetic ester @ 40°C Change Interval 2,000 hours Monthly oil analysis Filtration β10≥200 (ISO 4406) Dual-stage 10μ absolute Condition Monitoring:

- Vibration: <4.5 mm/s RMS (ISO 10816-3)

- Thermography: ΔT<28°C bearing-to-housing

- Ferrography: PQ index <90 for continued operation

Timken’s field data shows proper installation and lubrication can extend bearing life by 200% in EMSCO 1600HP pumps, reducing unplanned downtime by 30% (Bearings – Forum Energy Technologies, Inc.).

Applications in Offshore Drilling

The specialized bearing architectures detailed in previous sections are deployed across diverse offshore drilling scenarios, each presenting unique operational challenges. From high-pressure oil extraction to abrasive slurry handling, these components form the mechanical backbone of critical drilling systems.

Oil & Gas Drilling

Offshore hydrocarbon extraction subjects mud pump bearings to extreme conditions:

- Pressure Extremes: Operate continuously at 5,000-7,500 psi in deepwater rigs, with transient spikes exceeding 10,000 psi during kick control (Bearings – Forum Energy Technologies, Inc.)

- Abrasive Media: Handle drilling fluids containing 15-25% solids by volume, including silica particles with Mohs hardness up to 7 (Introduction and application fields of mud pump bearings-NEWS-FV)

- Material Solutions:

- Case-hardened 35CrMo alloy for crankshaft bearings (HRC 58-62)

- WC-10Co HVOF coatings on crosshead pins (5x wear resistance vs. chrome plating)

- Fluorocarbon seals for H₂S resistance >50ppm

Bearing selection follows a rigorous performance matrix:

| Application | Preferred Bearing Type | Key Selection Factor |

|---|---|---|

| Crankshaft | Tapered roller (180RIU684) | Combined axial/radial load balance |

| Connecting Rod | Spherical roller (22230 CA/W33) | Misalignment compensation |

| Crosshead | Needle roller (5G254936Q) | High load density in confined space |

| Auxiliary Systems | Hybrid ceramic deep groove | 260°C thermal stability |

Recent field data from Gulf of Mexico operations shows spherical roller bearings deliver 23% longer service life than conventional designs in floating rig applications, compensating for vessel pitch/roll up to 3° (PDFRoller Bearings in SOILMEC Triplex Pump).

Mining and Construction

Subsea mineral extraction and tunneling equipment leverage mud pump bearings in slurry transport systems:

- Durability Requirements:

- 10,000+ hours MTBF in continuous dredging operations

- 50% higher impact resistance for rock fragment ingress

- Specialized Designs:

- Rubber-lined spherical bearings for vibration damping (20% reduction in harmonic resonance)

- Tungsten carbide-coated rollers for sand slurry pumps (3x lifespan in 30% solids concentration)

- Split cylindrical bearings (NUP464776Q4/C9YA4) for in-situ maintenance (Mud Pump Bearings NUP464776Q4/C9YA4)

Offshore placer mining operations report 40% reduction in bearing-related downtime through the use of polymer cage spherical rollers in dredge pumps handling 5-15mm particulate loads (RKB cylindrical roller bearings for EMSCO mud pumps).

Waste Management

Drilling waste processing systems employ bearings adapted for corrosive and abrasive environments:

Wastewater Handling:

- Zirconia ceramic bearings for pH 2-12 fluid ranges

- PPS composite cages resisting chlorine attack

- 316L stainless steel races for chloride >10,000ppm

Sludge Dewatering:

- Tapered thrust bearings (T711 series) handling 800 kN axial loads

- Labyrinth seals with purge grease systems (QZ-2 grease intervals extended to 2,000 hours)

Thermal Processing:

- Silicon nitride hybrid bearings for 300°C thermal oxidation units

- Graphite-impregnated retainers for dry running capability

Field data from North Sea platforms demonstrates angular contact ball bearings with 40° contact angles achieve 50,000+ hours MTBF when processing oil-based drill cuttings with synthetic ester lubricants (Ceramic Matrix Composite Bearings).

Enhancing Drilling Efficiency with Proper Bearing Selection

Optimal bearing selection is the cornerstone of offshore drilling efficiency, directly impacting operational uptime and maintenance costs. The right bearing architecture can reduce unplanned downtime by up to 30% while extending equipment lifespan beyond API 7K’s 25,000-hour L10 requirement (PDFHow to Increase Mud Pump Bearing Life – The Timken Company). This section examines critical selection parameters, field-proven applications, and emerging technologies that redefine performance benchmarks in extreme drilling environments.

Key Selection Criteria

Six interdependent factors dictate bearing suitability for offshore mud pumps:

Load Profile Analysis:

- Radial/axial load ratios exceeding 3:1 mandate tapered roller designs (180RIU684)

- Transient shock loads >1,200 kN require case-carburized spherical rollers (22230 CA/W33 series)

- Pulsating loads demand cylindrical rollers with 150-180° load zones (NUP464776Q4/C9YA4)

Environmental Resilience:

Condition Bearing Solution Performance Benchmark 25% solids concentration W33-sealed spherical rollers 23% longer life vs. standard H₂S >50ppm Fluorocarbon seals + ceramic hybrids 2x corrosion resistance 150°C+ temperatures Silicon nitride rollers 35% friction reduction at 2k RPM Speed-Temperature Balance:

- Standard steel bearings: 120-150 RPM (continuous)

- Hybrid ceramic-steel: Up to 3,000 RPM (auxiliary systems)

- Thermal breakdown threshold: 93°C oil sump temperature (PDFAPI Standard 610)

Misalignment Compensation:

- Spherical rollers accommodate 3° shaft deflection

- Tapered designs (TDO assemblies) maintain <0.001″ alignment at 5,000 psi

Maintenance Accessibility:

- Split cylindrical bearings enable 40% faster in-situ replacements

- Pre-greased W33 grooves extend lubrication intervals to 2,000 hours

Standard Compliance:

- API 7K dynamic load minimums: 850 kN (cylindrical), 1,080 kN (spherical)

- ISO 281:2007 modified life formula accounts for contamination (κ) and lubrication (ηc) factors

Case Studies

Gulf of Mexico Deepwater Application

Schaeffler spherical roller bearings (24060 CA/W33C3) in SOILMEC TPK 2200 pumps demonstrated:

- 32,000 hours MTBF at 18% solids loading

- 3° continuous misalignment tolerance during hurricane conditions

- 15% lower maintenance costs vs. conventional bearings (PDFRoller Bearings in WIRTH Triplex Pump)

Arctic Drilling Rig Retrofit

Timken’s hybrid ceramic tapered bearings (T711 series) achieved:

- 260°C operational capability (-50°C cold starts)

- 113% longer lifespan in high-salinity conditions

- Elimination of cold-start lubrication failures (Ceramic Matrix Composite Bearings)

Middle East Slurry Handling

HNA’s API 7K-certified cylindrical rollers (NUP464777Q4) delivered:

- 3x wear resistance in 30% abrasive sand mixtures

- 200% longer service life than OEM specifications

- Full interchangeability with F1600 pump models (API Certified Replacement Bearings)

Future Trends

Smart Bearings Integration:

- Embedded IoT sensors monitoring:

- Real-time load distribution (±5% accuracy)

- Lubricant degradation (PQ index <90)

- Micro-vibration patterns (4.5 mm/s RMS threshold)

- Embedded IoT sensors monitoring:

Advanced Material Systems:

- Zirconia-toughened alumina liners (40% wear reduction)

- Graphene-enhanced cages (50% higher thermal conductivity)

- Self-healing composite seals (1,500+ hours H₂S resistance)

Eco-Efficient Designs:

- Dry-running capabilities up to 300°C

- 100% recyclable bearing assemblies

- Bio-degradable grease formulations

Performance Benchmarking:

Technology Current Benchmark 2030 Projection Hybrid Ceramic Bearings 50,000 hours MTBF 80,000 hours Dynamic Load Capacity 1,200 kN (spherical) 1,800 kN Temperature Range -50°C to +260°C -70°C to +400°C

These advancements align with IADC’s roadmap for zero-unplanned-downtime drilling, where bearing reliability directly contributes to 15% operational cost reductions in ultra-deepwater projects (PDFIADC Guidance for UBO and MPD Techniques).