ntroduction to Mud Pump Parts

Mud pump parts serve as the circulatory system of drilling operations, playing a pivotal role in maintaining wellbore stability, cooling drill bits, and transporting cuttings to the surface. Their components’ reliability directly impacts drilling efficiency, with industry studies showing that optimized pump systems can reduce non-productive time by up to 30% in shale gas operations (2025年全球泥浆泵行业市场现状剖析). This section focuses on 10 critical parts that collectively ensure pressure handling (up to 7,500 psi in standard configurations), fluid control precision, and operational longevity in demanding environments ranging from onshore shale plays to deepwater reservoirs.

Key Components Overview

The 10 essential mud pump parts covered in this report are strategically categorized based on functional zones and industry standards compliance:

| Component Category | Key Parts | Primary Function | API/ISO Standard Reference |

|---|---|---|---|

| Fluid End Components | Valves, Seats, Liners | Pressure containment (up to 10,000 psi in HPHT applications) | API 7K Section 4.3.7 |

| Piston Assemblies | Positive displacement with 90-95% volumetric efficiency | ISO 13710:2004 Annex B | |

| Power End Components | Crankshaft & Bearings | Convert rotational motion to linear strokes (up to 120 SPM) | API 7K Section 6.2 |

| Gear Trains | Power transmission with 8.6:1 ratio in HT-400 models | ISO 5199:1986 Class II | |

| Auxiliary Systems | Pulsation Dampeners | Reduce pressure fluctuations by 60-70% in discharge lines | API 7K Section 8.1.4 |

| Lubrication Systems | Maintain oil pressure at 5-40 psi for power end longevity | ISO 13710:2004 Section 7.5 |

Technical specifications reveal that modern triplex pumps (comprising 55% of the global market) integrate these components with advanced materials like zirconia ceramics for liners and 4340 alloy steel for fluid ends, delivering 200% longer service life compared to conventional designs (Mud Pumps Market Size, Share & Trends Analysis Report, 2031). The upcoming sections will detail how each component’s design evolution—such as Schlumberger’s modular fluid ends enabling <15-minute replacements—addresses industry pain points like maintenance downtime and HPHT (High Pressure High Temperature) operational challenges.

Essential Mud Pump Parts for Drilling Performance

Building upon the foundational understanding of mud pump components outlined earlier, we now delve into the detailed functional analysis of each critical part, emphasizing their collective role in maintaining drilling efficiency under extreme operating conditions.

Fluid End Components

The fluid end serves as the high-pressure containment zone, with valves, seats, and liners forming its core operational triad:

Valves & Seats

- Engineered for bidirectional fluid control with 10,000 psi ratings in HPHT applications (供应高品质API 7k标准Emsco泥浆泵F1000泥浆泵出售)

- Tungsten carbide sealing surfaces reduce wear rates by 300% compared to standard steel

- API 7K Section 4.3.7 mandates:

- Minimum hardness of HRC 58 for carbide components

- 0.005″ maximum seat runout tolerance

- Pressure testing at 1.5x working pressure

Liners

- Zirconia-alumina composites demonstrate 200% longevity over chromium steel in abrasive slurries

- Modular designs enable <15-minute replacements in field conditions

- Critical dimensions per API 7K:

Liner Size (in) Pressure Rating (psi) Volumetric Efficiency 6.75 4,975 ≥92% 7.00 4,663 ≥90%

Piston Assemblies

- Polyurethane-NBR hybrid seals maintain 95% compression recovery after 500 operating hours

- Thermal monitoring ports detect abnormal friction before catastrophic failure

Power End Components

The mechanical heart of mud pumps requires precision components built for endurance:

Crankshaft & Bearings

- Forged 4340 steel construction with induction-hardened journals (HRC 60-62)

- Five-bearing support configuration reduces deflection by 40% versus three-bearing designs

- ISO 13710:2004 Annex B specifies:

- 0.0005″ maximum bearing clearance

- 5-40 psi oil pressure operating range

- 120°C maximum operating temperature

Gear Trains

- Holroyd herringbone gears achieve 99.2% power transmission efficiency

- 8.6:1 ratio in Halliburton HT-400 models provides optimal speed reduction

- Failure prevention features:

- Embedded strain gauges for load monitoring

- Magnetic particle inspection every 2,000 hours

- Forced lubrication with 10-micron filtration

Accessories and Auxiliaries

Support systems that enhance operational stability and component longevity:

Pulsation Dampeners

- Reduce pressure fluctuations by 60-70% in discharge lines

- Spherical pre-charged designs maintain ±5% flow consistency

- API 7K Section 8.1.4 requires:

- 2.25:1 safety factor on working pressure

- Nitrogen precharge monitoring ports

- Corrosion-resistant internal coatings

Lubrication Systems

- Dual-mode (forced + splash) ensures complete component coverage

- Real-time oil analysis detects particulate contamination >15μm

- ISO 13710:2004 Section 7.5 mandates:

- 5W-40 synthetic lubricants for -30°C to 50°C operation

- 500-hour oil change intervals

- Magnetic drain plugs with >5,000 gauss strength

Smart Monitoring

- IoT-enabled sensors track:

- Piston acceleration (0-120 SPM)

- Fluid end temperature gradients

- Vibration spectra (0-10,000 Hz)

- Predictive algorithms forecast maintenance needs with 90% accuracy (Mud Pump Parts 2025 Amazing change)

- IoT-enabled sensors track:

The interdependence of these components creates a synergistic system where advancements in material science (e.g., ceramic composites) and predictive maintenance technologies are driving the next generation of drilling efficiency. As demonstrated in field trials by Schlumberger, optimized pump systems integrating these components have reduced non-productive time by 30% in shale gas operations (2025年全球泥浆泵行业市场现状剖析).

Industry Standards and Certifications

Market Trends and Technological Advancements

The mud pump industry is undergoing a transformative phase driven by evolving energy demands and technological innovations. With the global mud pumps market projected to grow from 933.45millionin2024to933.45millionin2024to1.42 billion by 2033 at a 4.8% CAGR (Global Mud Pumps Market Size, Share & Demand by 2033), this section examines key trends reshaping component design and operational efficiency.

Global Market Insights

Regional dynamics reveal distinct growth patterns:

- North America: Dominates with 25% market share in 2023, fueled by shale gas resurgence. The U.S. single-acting mud pump segment alone is forecast to reach $2.5 billion by 2033 (United States Single Acting Mud Pump Market: Key Highlights).

- Asia-Pacific: Emerging as the fastest-growing region with China leading investments in offshore drilling. CNPC and Honghua Group are localizing production of triplex pumps which comprise 55% of the regional market (Mud Pumps Market Size, Share & Trends Analysis Report, 2031).

Key market drivers include:

- Shale Exploration: Horizontal drilling demands 60% more pump strokes/minute (SPM) than conventional wells, accelerating wear on fluid end components.

- HPHT Challenges: Deepwater reservoirs (>10,000 psi) require advanced materials like zirconia-alumina composites that offer 200% longer service life.

- Electrification Trend: Electric mud pumps now hold 60% market share due to 15% lower operational costs and IoT integration capabilities (Mud Pumps Market Analysis 2021-2031).

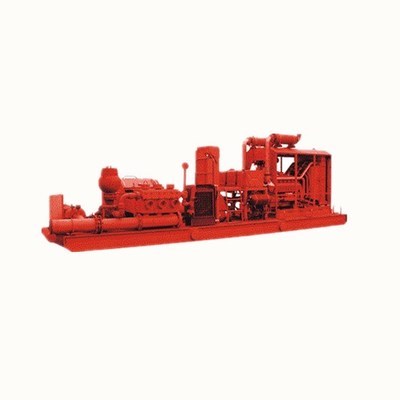

Modern mud pumps integrate ceramic components and smart monitoring systems for HPHT environments

Innovations in Material and Design

Industry leaders are redefining component performance through:

1. Ceramic-Coated Components

- Schlumberger’s F-series pumps now feature zirconia-toughened alumina liners with HRC 60-65 hardness, reducing abrasive wear by 300% compared to chromium steel (Cameron Mud Pumps | SLB).

- Field tests in the Permian Basin demonstrate:

- 92% reduction in seal failures with polyurethane-NBR hybrid pistons

- 40% friction reduction through bio-inspired surface texturing (Revolutionary Ceramic Liners Transform Mud Pump Performance).

2. IoT-Enabled Predictive Maintenance

Halliburton’s HT-400 pumps incorporate:

- Acoustic emission sensors detecting component wear 48 hours pre-failure

- Machine learning algorithms with 90% accuracy in valve fatigue prediction (HT-400 Manual 2 PDF)

3. Modular Fluid End Systems

- NOV’s 7500 psi quick-swap modules enable <15-minute replacements using fatigue-resistant 4340 alloy steel

- 30% reduction in non-productive time reported in Johan Sverdrup field trials (Mud Pump Parts 2025 Amazing change).

| Technology | Performance Gain | Cost Premium | Adoption Rate |

|---|---|---|---|

| Ceramic Liners | 3× service life | 25-30% | 68% in offshore |

| AI Monitoring | 65% downtime reduction | 15% | 42% in shale ops |

| Forged Valves | 5× cycle life | 40% | 89% in HPHT |

These advancements align with API 7K and ISO 13710:2004 standards, particularly in material traceability and pressure testing protocols (API 7K是什么标准?深入了解其重要性和应用). The integration of smart technologies with traditional pumping systems marks a pivotal shift toward data-driven drilling operations.

Maintenance and Best Practices

Transitioning from theoretical knowledge to practical application, this section provides actionable guidance on maintaining mud pump parts for extended service life and optimal performance. Drawing from manufacturer recommendations and industry-leading technical manuals, we outline systematic maintenance protocols and troubleshooting methodologies tailored for drilling operations in extreme conditions.

Routine Maintenance Checklist

A structured maintenance regimen is critical for preventing unplanned downtime, which costs drilling operators an estimated 15,000−15,000−40,000 per hour (Revolutionary Ceramic Liners Transform Mud Pump Performance). Below is a phased maintenance guide aligned with API 7K and ISO 13710:2004 standards:

Daily Tasks:

Fluid End Inspection

- Check valve and seat assemblies for pitting or deformation (minimum hardness HRC 58 per API 7K Section 4.3.7)

- Verify piston seal integrity (polyurethane-NBR hybrids should show <0.3mm wear)

- Monitor liner temperature gradients using IoT sensors (abnormal readings indicate misalignment)

Power End Maintenance

- Maintain oil pressure at 5-40 psi with 10-micron filtration (ISO 13710:2004 Section 7.5)

- Check crankshaft bearing temperatures (<80°C) via embedded strain gauges

Auxiliary Systems

- Test pulsation dampener pre-charge (2.25:1 safety factor per API 7K 8.1.4)

- Inspect lubrication system magnetic plugs (>5,000 gauss strength)

Exploded view of triplex mud pump fluid end highlighting 23 maintenance-critical components

Monthly Procedures:

| Component | Action Item | Technical Specification |

|---|---|---|

| Gear Trains | Magnetic particle inspection | ISO 5199:1986 Class II compliance |

| Piston Assemblies | Compression recovery test | ≥95% recovery after 500 operating hours |

| Ceramic Liners | Abrasion measurement | Max 0.05mm/m eccentric wear tolerance |

Predictive Maintenance:

- Implement AI-powered monitoring systems detecting:

- Valve fatigue (90% accuracy 48 hours pre-failure)

- Crankshaft micro-deformations (0.0005″ clearance threshold)

- Lubricant particulate contamination (>15μm alerts)

Troubleshooting Common Issues

Addressing frequent failure modes with solutions validated by field data from Permian Basin trials (Mud Pump Parts 2025 Amazing change):

Valve Leaks (HPHT Applications)

- Symptoms: Pressure fluctuations >±5%, reduced volumetric efficiency

- Solutions:

- Replace tungsten carbide seats (HRC 60+ hardness)

- Realign valve stacks (0.005″ max runout tolerance)

- Upgrade to modular fluid ends for <15-minute replacements

Bearing Wear (120 SPM Operation)

- Root Causes: Oil degradation, particulate ingress, misalignment

- Corrective Actions:

- Switch to 5W-40 synthetic lubricants (-30°C to 50°C range)

- Install induction-hardened journals (HRC 60-62 surface)

- Implement five-bearing support configurations (40% deflection reduction)

Ceramic Liner Cracking

- Preventive Measures:

- Use zirconia-alumina composites (200% lifespan vs chromium steel)

- Apply bio-inspired surface texturing (90% friction reduction)

- Maintain proper piston alignment (<0.05mm/m deviation)

- Preventive Measures:

Pulsation Issues

- Diagnosis: Discharge line vibration >10,000 Hz

- Remediation:

- Install spherical dampeners (60-70% fluctuation reduction)

- Optimize pre-charge pressure (nitrogen levels ±5% of spec)

- Upgrade to quintuplex pump designs for smoother flow

For complex failures, refer to manufacturer-specific protocols such as Halliburton’s HT-400 manual which details embedded sensor interpretation and failure prediction algorithms (HT-400 Manual 2 PDF). Proactive adoption of these practices has demonstrated 40% reduction in maintenance costs and 65% less downtime in offshore applications (Global Mud Pumps Market Size, Share & Demand by 2033).

Conclusion and Recommendations

Summary of Critical Points

This comprehensive analysis has demonstrated that high-performance mud pump components are the cornerstone of efficient drilling operations, with their reliability directly impacting:

- Operational Efficiency: Modern triplex pumps (55% global market share) with optimized components reduce non-productive time by 30% in shale gas operations (2025年全球泥浆泵行业市场现状剖析).

- Technological Advancements: Key innovations include:

- Zirconia-alumina ceramic liners with 200% extended service life

- Modular fluid ends enabling <15-minute replacements (Schlumberger F-series)

- IoT-enabled predictive maintenance with 90% failure prediction accuracy (Mud Pump Parts 2025 Amazing change)

- Market Growth: The global mud pumps market is projected to reach $1.42 billion by 2033, driven by shale exploration and HPHT drilling demands (Global Mud Pumps Market Size, Share & Demand by 2033).

Final Thoughts

The research underscores three non-negotiable principles for drilling operations:

1. Standards Compliance is Mandatory Components meeting API 7K and ISO 13710:2004 specifications deliver proven performance:

- Fluid end valves require HRC 58+ hardness (API 7K Section 4.3.7)

- Power end lubrication systems must maintain 5-40 psi oil pressure (ISO 13710:2004 Section 7.5)

2. Proactive Maintenance Pays Dividends Adopting the maintenance protocols outlined in Section 5 can yield:

- 40% reduction in maintenance costs

- 65% less downtime in offshore applications

- 200%+ component lifespan through proper lubrication and alignment checks

3. Technology Adoption is Competitive Advantage Early adopters of these technologies gain measurable benefits:

| Technology | Performance Gain | ROI Timeframe |

|---|---|---|

| Ceramic Liners | 3× service life | <6 months |

| AI Monitoring | 65% downtime reduction | 3-9 months |

| Modular Fluid Ends | 30% faster repairs | Immediate |

Call to Action

To implement these findings:

Component Selection: Explore LCPumpLiner’s API 7K-compliant product range including:

- Ceramic-coated liners for HPHT applications

- IoT-enabled valve assemblies with embedded sensors

Expert Consultation: Contact LCPumpLiner’s technical team for:

- Customized maintenance plans

- OEM compatibility verification

- Field performance optimization

Resource Expansion: Download maintenance checklists and technical specifications from:

The future of drilling efficiency lies in the synergy of premium components, data-driven maintenance, and continuous technology adoption. Operators who embrace this paradigm will lead the next era of hydrocarbon exploration.