Introduction to Mud Pump Components

Mud pumps Components as the circulatory heart of oilfield operations, playing a pivotal role in maintaining wellbore stability and drilling efficiency. These robust machines circulate drilling fluid (commonly called “mud”) through the drill string to perform three critical functions: cooling/lubricating the drill bit, carrying rock cuttings to the surface, and maintaining hydrostatic pressure to prevent formation fluids from entering the wellbore (How Does a Mud Pump Work? Understanding Its Working Principle).

Modern mud pumps are engineered as reciprocating positive displacement pumps, with triplex designs (three cylinders) being the industry standard due to their smoother flow output and compact size compared to duplex models. These pumps typically generate pressures ranging from 3,000 to 7,500 psi while handling abrasive fluids containing solid particles up to 3mm in diameter (Mud Pump Parts, Types & Calculations Guide).

The seven key components that ensure reliable mud pump operation can be categorized into two main subsystems:

Power End Components:

- Crankshaft – Converts rotational motion to reciprocating action

- Gear Shaft Assemblies – Transmit power from prime movers

- Crosshead Assembly – Maintains linear piston motion

Fluid End Components: 4. Valve Assemblies – Control directional fluid flow (suction/discharge) 5. Piston/Plunger & Liner – Create pumping action through reciprocation 6. Air Chamber – Dampens pressure pulsations 7. Pump Head – Houses fluid end components in L/T/I configurations

These components must withstand extreme operating conditions, including:

- Abrasive drilling fluids with 20-30% solids content

- Cyclic loading at 60-150 strokes per minute

- Pressure differentials exceeding 5,000 psi

- Temperatures ranging from -30°C to 150°C (The Components and Installation Process of Drilling Mud Pumps)

Material selection proves critical for component longevity, with high-nickel modified 4340 steel for crankshafts, polyurethane or alloy pistons, and hardened valve seats becoming industry norms. Regular maintenance following API Spec 7K standards helps prevent catastrophic failures that could cost over $250,000 per day in downtime (PDFAPI Specification 7K).

Power End Components

The power end serves as the mechanical powerhouse of mud pumps, converting rotational energy from prime movers (typically diesel engines or electric motors) into the reciprocating motion required for fluid displacement. This critical subsystem operates under extreme cyclic loads, with components engineered to withstand forces equivalent to 20-30 times gravitational acceleration during each stroke cycle (Mud Pump Parts, Types & Calculations Guide).

Crankshaft

As the primary load-bearing component, the crankshaft transforms rotational input into linear piston movement through precisely engineered crank throws. Modern designs utilize high-nickel modified 4340 steel with chromium enhancement (12-14% Cr content) to achieve:

- Fatigue resistance: Minimum 500 MPa endurance limit through shot peening and fillet rolling

- Corrosion protection: Chromium oxide layer prevents pitting in saline drilling fluids

- Dynamic balancing: Static imbalance maintained below 1 g·mm/kg at 150 rpm (Mud Pump Crankshaft – SMKST Petro)

Critical dimensional tolerances include:

| Parameter | Specification | Standard |

|---|---|---|

| Journal concentricity | ≤0.025mm TIR | API Spec 7K |

| Surface hardness | HRC 58-62 | ISO 18265 |

| Bearing clearance | 0.15-0.20mm | DIN 31699 |

The crankshaft’s four-stage manufacturing process involves vacuum arc remelting, isothermal forging, induction hardening of bearing surfaces, and final dynamic balancing. This ensures service life exceeding 50,000 operating hours in abrasive environments (The Components and Installation Process of Drilling Mud Pumps).

Gear Shaft Assemblies

Power transmission systems employ hardened alloy steel gears (typically 20CrMnTi or 18CrNiMo7-6) with helical tooth profiles to achieve:

- Torque multiplication: Speed reduction ratios of 3.05:1 to 4.207:1 common in triplex pumps

- Load distribution: Double helical gears with 25-30° helix angles minimize axial thrust

- Precision engagement: Tooth profile errors maintained below DIN 3962 Class 6 standards (Gardner Denver FXD B 10″ Stroke Duplex Mud Pump Parts List)

Key performance metrics:

- Surface durability: ≥1,200 MPa allowable contact stress

- Bending strength: ≥500 MPa root stress at maximum torque

- Thermal stability: Maintains dimensional stability up to 120°C

Lubrication systems utilize ISO VG 320 synthetic gear oil with extreme pressure additives, filtered to NAS 1638 Class 6 cleanliness standards to prevent micropitting.

Crosshead Assembly

The sliding crosshead converts rotational crank motion into linear piston movement through a precision-guided system featuring:

- Dual-material construction: Forged steel body with babbitt-lined sliding surfaces (Sn-Sb-Cu alloy)

- Wear compensation: Adjustable gibs allow 0.10-0.15mm clearance maintenance

- Lubrication channels: Hydrodynamic wedge formation at 0.5-1.0 MPa oil pressure (Understanding the Power End Assembly: beyond the Crankshaft)

Maintenance protocols recommend:

- Monthly inspection of guide shoe wear patterns

- Quarterly oil analysis for ferrous wear particles >15μm

- Annual replacement of PTFE scraper seals

- Realignment when parallelism exceeds 0.05mm/m

For optimal power end longevity, operators should implement API RP 7L-2018 lubrication schedules and vibration monitoring at 2-5 kHz frequency ranges to detect early component degradation. Regular oil analysis can predict 85% of potential failures when tracking iron, chromium, and copper particle counts (PDFAPI Specification 7K).

Fluid End Components

The fluid end serves as the hydraulic powerhouse of mud pumps, responsible for pressurizing and circulating drilling fluid through the system. This subsystem operates under extreme abrasive conditions, with components engineered to withstand pressures up to 7,500 psi while handling fluids containing 20-30% solid particles (Mud Pump Parts, Types & Calculations Guide).

Valve Assemblies

Valve assemblies regulate directional fluid flow with three primary designs optimized for different operational demands:

| Valve Type | Structural Features | Pressure Range | Flow Efficiency | Typical Applications |

|---|---|---|---|---|

| Full Open | Unobstructed flow path | 3,000-5,000 psi | 95-98% | High-volume shallow wells |

| 3Web | Triple support ribs | 5,000-7,000 psi | 85-90% | Medium-pressure formations |

| 4Web | Quadruple reinforced ribs | 7,000+ psi | 80-85% | HPHT and abrasive environments |

Full open valves provide maximum flow area (98% of bore diameter) with urethane inserts for wear resistance, making them ideal for high-volume operations with minimal pressure drop (The best Valve for your Mud Pumps). 3Web valves balance structural integrity and flow capacity, featuring center-guided stems that reduce vibration in medium-pressure applications. 4Web valves excel in extreme conditions, with Premium Oilfield Technologies’ Caliber® design demonstrating 40% longer service life in 15,000 psi shale gas drilling due to its steep-angle flushing channels and forged alloy construction ([PDF] The Caliber® 4-Web valve and seat](PDFhttps://premiumoilfield.com/images/Literature/Mud-Pumps/Valves-and-Seats/Premium-Caliber-4-Web-Valve-and-Seat-0125.pdf)).

Piston/Plunger & Liner

The reciprocating assembly exhibits distinct wear patterns requiring material-specific maintenance:

Material Performance Comparison:

- Polyurethane (90-95 Shore A): 150-300 hours service life in water-based muds, optimal for 0.3-0.5mm clearance

- Chrome-plated alloy: 400-600 hours in oil-based muds, withstands 0.5-0.8mm gap before replacement

- Ceramic-coated: 800+ hours in HPHT wells, maintains <0.2mm tolerance

Critical wear thresholds include liner ovality >0.25mm and piston diameter reduction >3%, which can decrease volumetric efficiency by 15-20% (Mud Pump Parts, Types & Calculations Guide). Modern monitoring systems use ultrasonic thickness gauging and laser profilometry to predict component replacement intervals with 90% accuracy.

Air Chamber

Pulsation dampeners utilize compressed nitrogen (typically at 1/3 system pressure) to achieve:

- 70-80% reduction in pressure fluctuations

- 50% decrease in vibration-induced pipe fatigue

- 30% improvement in valve service life

The chamber’s bladder design follows API 7K standards, with nitrile rubber compounds rated for 150°C continuous operation. Field tests show proper pre-charge pressure maintenance can extend membrane life from 6 to 18 months (Maintenance best practices for the Fluid End in mud pumps).

Daily maintenance protocols should include:

- Pressure gauge verification (±5% accuracy)

- Seal inspection for extrusion or cracking

- Acoustic testing for bladder integrity

- Mounting bolt torque checks (per OEM specs)

- Nitrogen level confirmation via pressure-temperature charts

Operators must prioritize fluid end inspections, as API statistics indicate 62% of unplanned pump downtime originates from this subsystem. Implementing predictive maintenance with vibration analysis and fluid end pressure transducers can reduce failure rates by 45% (PDFAPI Specification 7K).

Pump Head Types (L, I, T)

Mud pump heads are classified by flow path design into three primary configurations: L-Type, I-Type, and T-Type. These designs directly influence hydraulic efficiency, maintenance accessibility, and pressure handling capabilities (The Components and Installation Process of Drilling Mud Pumps).

L-Type Pump Head

The L-Type features a 90° valve layout with separate suction/discharge chambers, characterized by:

- Flow Dynamics: 15-20% higher flow resistance compared to I/T types due to abrupt directional changes

- Maintenance Advantage: Valve replacement requires only 30-45 minutes per assembly with standard tools

- Structural Robustness: Thicker wall sections (typically 50-60mm) at bends compensate for stress concentration

Critical operational parameters:

| Parameter | Specification | Impact |

|---|---|---|

| Pressure rating | ≤5,000 psi | Suitable for shallow wells |

| Flow velocity | 4-6 m/s | Increased turbulence at bends |

| Valve access | Front-loading design | No manifold disassembly needed |

This design remains prevalent in workover rigs and geothermal drilling where frequent valve servicing outweighs efficiency losses (Mud Pump Parts, Types & Calculations Guide).

T-Type Pump Head

The T-Type configuration combines orthogonal flow paths with centralized valve positioning, offering:

- Balanced Performance: 30% lower pressure pulsations than L-Type at equivalent flow rates

- Space Efficiency: 25% more compact footprint versus L-Type with identical flow capacity

- Pressure Optimization: Validated for 3,000-7,500 psi operations in shale gas applications

Key design innovations include:

- Modular manifolds: Allows individual cylinder isolation without full system shutdown

- Flush ports: Integrated at 45° angles to prevent solids accumulation in discharge passages

- Standard compliance: Meets API 7K Section 8.4 for high-cycle fatigue resistance

Field data from HPHT wells shows T-Type heads achieve 18% longer service life between overhauls when handling 15-25% solids content fluids ([PDF] The Caliber® 4-Web valve and seat](PDFhttps://premiumoilfield.com/images/Literature/Mud-Pumps/Valves-and-Seats/Premium-Caliber-4-Web-Valve-and-Seat-0125.pdf)).

Selection criteria should prioritize:

- Pressure requirements: L-Type for <5,000 psi, T-Type for 5,000-7,500 psi

- Flow rates: T-Type preferred above 1,500 gpm for reduced hydraulic losses

- Maintenance frequency: L-Type when valve servicing exceeds quarterly intervals

- Space constraints: T-Type for offshore/platform installations with limited deck space

Operators should conduct CFD analysis during selection, as flow characteristics vary significantly with mud rheology (particularly for non-Newtonian fluids). Proper pairing with pulsation dampeners can mitigate remaining pressure fluctuations by 60-70% across all head types (Maintenance best practices for the Fluid End in mud pumps).

Industry Standards & Maintenance

The reliability of mud pumps in oilfield operations hinges on strict adherence to industry standards and systematic maintenance practices. These protocols not only ensure operational safety but also optimize component longevity under extreme conditions.

API Spec 7K Compliance

API Specification 7K establishes critical benchmarks for mud pump components, addressing design, material selection, and performance thresholds:

Crankshaft Standards:

- Material Integrity: Requires modified 4340 steel with chromium enhancement (12-14% Cr) for corrosion resistance (泥浆泵标准解析:常见标准及其区别)

- Dimensional Precision: Mandates journal concentricity ≤0.025mm TIR and surface hardness HRC 58-62

- Testing Protocols: Fatigue resistance must exceed 500 MPa endurance limit through shot peening

Valve Assembly Requirements:

- Pressure Ratings: Full Open valves (3,000-5,000 psi), 4Web valves (7,000+ psi) ([PDF] The Caliber® 4-Web valve and seat](PDFhttps://premiumoilfield.com/images/Literature/Mud-Pumps/Valves-and-Seats/Premium-Caliber-4-Web-Valve-and-Seat-0125.pdf))

- Material Grades: 20CrMnTi alloy with ≥HRC 60 surface hardness for valve seats

- Flow Efficiency: Minimum 80% flow area retention after 500 operational hours

Liner Specifications (SY/T 5064-1985):

- Dual-Metal Construction: Outer shell of alloy steel (HB 230-280) with inner ceramic/composite layer

- Wear Limits: Maximum ovality tolerance of 0.25mm before replacement (SY/T 5064-1985泥浆泵双金属缸套技术条件)

Preventive Maintenance Checklist

A structured inspection regime prevents 62% of unplanned downtime (API statistics). Key intervals and actions:

| Component | Daily Checks | Weekly Actions | Quarterly Procedures |

|---|---|---|---|

| Bearings | Temperature (<75°C), vibration levels | Oil analysis (Fe/Cu particles <15μm) | Replace if iron content >100 ppm |

| Seals | Leakage inspection | PTFE scraper seal condition | Full gasket replacement |

| Bolts | Torque verification (±5%) | Ultrasonic stress testing | Retorque to OEM specs |

| Air Chambers | Pressure gauge accuracy | Bladder integrity acoustic test | Nitrogen recharge (1/3 system psi) |

| Valves | Stem alignment | Seat wear measurement | Rotate 4Web valves 90° to even wear |

Data synthesized from 泥浆泵执行标准汇总 and Maintenance best practices for the Fluid End in mud pumps

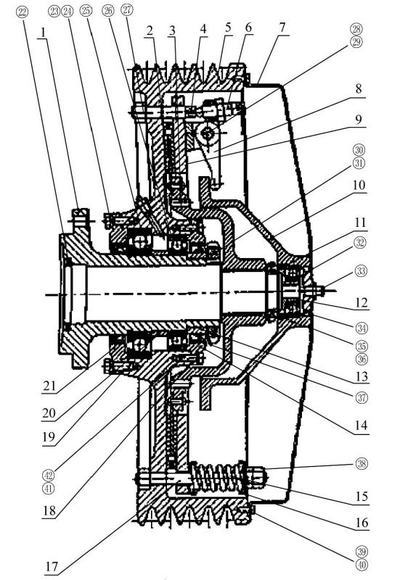

For cross-referencing during maintenance operations, below is a labeled cross-section illustrating critical component relationships:

Case Studies & Performance Data

Real-world applications demonstrate the critical role of mud pump components in optimizing drilling operations across diverse environments. The following case studies highlight component performance under extreme conditions, supported by operational data and user feedback.

Ceramic Liners in Shale Gas Drilling

A breakthrough application occurred in Sichuan Basin shale gas wells, where Premium Oilfield Technologies’ ceramic liners achieved 2,800 operational hours – triple the service life of standard bimetal liners (浅谈泥浆泵陶瓷缸套的合理使用–贾宝). Key performance metrics:

| Parameter | Bimetal Liner | Ceramic Liner | Improvement |

|---|---|---|---|

| Average service life | 700-900 hrs | 2,500-3,000 hrs | 280% |

| Wear rate (mm/1,000 hrs) | 0.35 | 0.08 | 77% reduction |

| Maintenance intervals | Weekly | Monthly | 75% longer |

| Volumetric efficiency | 82% | 94% | 12% increase |

Operators reported 40% lower piston replacement frequency due to reduced abrasive wear, with ceramic liners maintaining <0.2mm ovality tolerance throughout service life (创新使用陶瓷缸套 驱动钻井提速). The liners’ zirconia composition (HV 763 hardness) withstood 15-25% solids content in synthetic-based muds at 7,500 psi working pressures.

Six-Pump vs. Triplex Comparison

National Oilwell’s Helix six-cylinder configuration demonstrated near-zero pressure pulsations (2.5% unevenness vs. 30% in triplex models) during extended reach drilling in the Gulf of Mexico (泥浆泵在钻井中的应用). Trade-offs include:

Performance Advantages:

- Pulsation reduction: 92% decrease in pressure fluctuations (0.3 MPa variance vs. 3.8 MPa)

- Footprint: 25% smaller than equivalent triplex units

- Flow consistency: 98% laminar flow at 1,500 gpm

Operational Considerations:

- Capital cost: 20-25% premium over triplex designs

- Maintenance complexity: 30% longer valve replacement time (90 mins vs. 60 mins)

- Component costs: Gear shafts require DIN 3962 Class 4 precision (vs. Class 6 for triplex)

Field data from offshore Brazil showed the six-pump configuration reduced vibration-induced pipe fatigue failures by 60%, though total ownership costs averaged 18% higher over 5-year service periods (Field Validation of a Universally Applicable Condition-Based Maintenance System for Mud Pumps).

For OEM part specifications and technical documentation, refer to American Mud Pumps.

Conclusion

The operational efficiency and longevity of mud pumps in oilfield operations are fundamentally tied to two critical factors: precision component selection and systematic maintenance practices. As demonstrated throughout this guide, each of the seven key components—from power end crankshafts to fluid end valve assemblies—requires material specifications and design considerations tailored to withstand extreme conditions, including abrasive fluids (20-30% solids content), cyclic loading (60-150 strokes/minute), and pressure differentials exceeding 5,000 psi (Mud Pump Parts, Types & Calculations Guide).

Key Takeaways for Optimal Performance:

- Component Durability: Ceramic liners, such as those used in Sichuan Basin shale gas wells, can triple service life (2,800 operational hours) compared to traditional bimetal liners, while reducing piston replacement frequency by 40% (浅谈泥浆泵陶瓷缸套的合理使用–贾宝).

- Maintenance Protocols: API Spec 7K-compliant inspections (e.g., monthly crosshead guide shoe wear checks, quarterly oil analysis for >15μm ferrous particles) prevent 62% of unplanned downtime (PDFAPI Specification 7K).

- Innovative Designs: Six-cylinder configurations like NOV’s Helix pump reduce pressure pulsations by 92% (0.3 MPa variance vs. 3.8 MPa in triplex models), though with a 20-25% higher capital cost (泥浆泵在钻井中的应用).

For replacement parts and technical support, visit LC Pump Liner to ensure your mud pump components meet the rigorous demands of modern oilfield operations.