Introduction to Mud Pump Liners

Mud pump liners are critical components in drilling operations, serving as replaceable cylindrical sleeves that line the interior of mud pumps. These liners play a vital role in protecting the pump’s internal components from the abrasive and corrosive effects of drilling fluids while maintaining pressure integrity during high-pressure circulation (What is Mud Pump Liner? Uses, How It Works & Top Companies). As the primary wear surface in reciprocating piston pump systems, they directly impact operational efficiency and equipment longevity in oil and gas, mining, and geothermal drilling applications.

Key Functions

Mud pump liners perform three essential functions that are critical to drilling operations:

Wear Protection

Liners act as sacrificial barriers against abrasive particles in drilling fluids, which can contain up to 21% solids by volume (Mud Pump Liners: 5 Key Factors for Optimal Drilling Performance). The inner surfaces of premium liners achieve surface finishes ≤0.8μm roughness (ceramic designs) to minimize piston wear. Modern materials like zirconia ceramics demonstrate 10x greater abrasion resistance compared to standard single-metal liners.Pressure Sealing

Designed to withstand cyclic pressures up to:- 7,500 psi in standard applications

- 10,000 psi in ultra-deep wells

(Mud Pump Liners: Which Choice Best Meets Your Drilling Needs?)

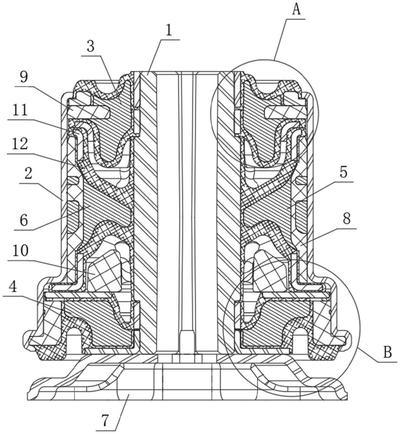

The cross-section structure (shown above) reveals how forged steel hulls and precision-machined sealing grooves maintain pressure containment even under extreme conditions.

Fluid Guidance

Liners ensure laminar flow of drilling fluids through precisely honed inner diameters (typically 4″-8″). This guidance function:- Reduces hydraulic losses by 15-20% in ceramic designs

- Maintains consistent flow rates critical for wellbore stability

- Prevents turbulent flow that accelerates component wear

Technical specifications vary by material type:

| Material | Hardness | Pressure Rating | Temp Range | H₂S Tolerance |

|---|---|---|---|---|

| Single Metal | HRC55-60 | 5,000 psi | -20°C to 120°C | 5 ppm |

| Bi-Metal | HRC60-65 | 7,500 psi | -20°C to 240°C | 10 ppm |

| Ceramic | HRA85-92 | 10,000 psi | -40°C to 350°C | 24 ppm |

| Nickel-Based Alloy | HRC60-64 | 8,500 psi | -50°C to 300°C | 50 ppm |

Data compiled from multiple sources including Mud Pump Liners: 5 Key Factors and Premium Oilfield Technologies

These functions collectively contribute to:

- 40-60% extended pump lifespan with proper maintenance

- 30% reduction in fluid end maintenance costs

- Compliance with API 7K and ISO 13534 standards for pressure cycling and material consistency

Materials and Types of Mud Pump Liners

Mud pump liners are manufactured from various materials to suit different drilling conditions, ranging from conventional onshore wells to extreme high-pressure/high-temperature (HPHT) environments. The material selection directly impacts wear resistance, corrosion tolerance, and operational lifespan, with four primary categories dominating the market.

Single Metal Liners

Constructed from monolithic 45# forged steel (AISI 1045), single metal liners undergo carburization and high-frequency treatment to achieve HRC58-62 hardness (Mud Pump Liners: Types, Processing & Maintenance Guide). Their cost-effectiveness (30% lower than bi-metal alternatives) makes them suitable for:

- Shallow wells with pressures ≤5,000 psi

- Non-corrosive drilling fluids (pH 7.5-10.2)

- Temperature ranges of -20°C to 120°C (Mud Pump Liners: 5 Key Factors)

Key limitations include reduced service life (~500 hours) in abrasive formations and lower H₂S tolerance (5 ppm max). The manufacturing process involves:

- Normalization at 800°C for 4-5 hours

- Rough machining of inner/outer diameters

- Final precision grinding to ≤0.8μm surface finish

Bimetal Liners

These liners combine AISI 1045 steel outer shells (tensile strength >900,000 psi) with centrifugally cast high-chromium iron inner sleeves (Cr content ≥27%) (Bi-Metal Mud Pump Liners – SMKST Petro). Key advantages include:

| Parameter | Specification |

|---|---|

| Hardness | HRC60-65 (inner sleeve) |

| Pressure Rating | 7,500 psi |

| H₂S Resistance | 22 ppm |

| Service Life | 800-1,200 hours |

The centrifugal casting process ensures metallurgical bonding between layers, with the inner sleeve achieving mirror-like finishes (Ra ≤0.4μm) for reduced piston wear. Bimetal liners excel in medium-abrasive conditions like shale gas drilling, where proppant concentrations reach 21% solids by volume (Bimetal Lined With High Chrome Alloy Pipe).

Ceramic Liners

Zirconia-based ceramic liners represent the pinnacle of wear resistance, demonstrating:

- 300% longer lifespan vs bi-metal in field tests (Revolutionary Ceramic Liners)

- HRA85-92 hardness (exceeding tungsten carbide)

- 10,000 psi pressure rating for ultra-deep wells

- Thermal stability up to 350°C with 16°C cooling systems

Advanced manufacturing combines cold-pressed zirconia/alumina nanopowders with high-temperature sintering, achieving fracture toughness of 3.7-3.8 MPa·m¹/². These liners are indispensable for:

- Geothermal wells (>300°C)

- HPHT reservoirs (15,000+ psi)

- High-abrasion formations (quartz content >40%)

Nickel-Based Alloy Liners

Specialized nickel alloys (e.g., INCONEL® C-276) provide unmatched corrosion resistance in sour gas environments:

- H₂S tolerance: 50+ ppm (Corrosion of nickel in acid solutions)

- Chloride resistance: 200,000 ppm

- Temperature range: -50°C to 300°C

These liners undergo solution annealing at 1,150-1,300°C followed by rapid quenching to prevent carbide precipitation. Their superior performance in acidic (pH <4) and high-H₂S environments comes at 5-8× the cost of bi-metal liners, justifying use primarily in:

- Sour gas wells (>50 ppm H₂S)

- CO₂ injection systems

- Offshore drilling with seawater-based muds

Material selection should consider both technical specifications and total cost of ownership, as shown in this comparative analysis:

Installation and Maintenance Best Practices

Proper installation and regular maintenance are critical to maximizing the lifespan of mud pump liners, which can extend operational efficiency by 40-60% and reduce fluid end maintenance costs by 30% (Mud Pump Liner and Piston Replacement: Best Practices Guide). These practices ensure optimal pressure sealing, wear resistance, and compliance with API 7K/ISO 13534 standards.

Installation Procedures

Cold Installation Method

For standard steel or bi-metal liners, follow these steps:

- Preparation: Clean the liner bore thoroughly and inspect for debris. Lubricate the outer surface with anti-seize compound (Processing Technology and Installation of Mud Pump Cylinder Liner).

- Alignment: Use wooden mallets to adjust eccentricity (<0.1mm) and ensure perpendicularity to the piston rod.

- Securing: Tighten clamp bolts to 966 ft-lbs torque for National 12-P-160 pumps ([PDF] 6576-22A NATIONAL 12-P-160 HYDRAULIC LINER RETAINER INSTRUCTIONS](PDFhttps://swoil.com/wp-content/uploads/2023/07/1549993608-6576-22A-NATIONAL-12-P-160-HYDRAULIC-LINER-RETAINER-INSTRUCTIONS_500.pdf)).

Hot Installation Method

Required for ceramic or nickel-alloy liners in HPHT environments:

- Thermal Treatment: Heat outer shell to 450-500°C for 5-6 hours while cooling inner sleeve to -50°C for shrink fit (Heat treatment method of mud pump cylinder liner).

- Pressure Testing: Conduct hydrostatic tests at 1.5x working pressure post-installation.

Critical precautions:

- Never strike liners directly with metal tools

- Verify cooling water flow (>10L/min at 0.2MPa) before operation

Maintenance Routines

Daily Checks

- Monitor pressure fluctuations (>±500 psi indicates wear)

- Inspect cooling systems for leaks or blockages

Weekly Tasks

- Measure liner ID wear using ultrasonic testing (replace if >15% wall thickness loss) (10 Key Insights About Mud Pump Liners)

- Lubricate piston rods with high-temperature grease

Monthly Procedures

| Task | Tool/Standard | Acceptable Threshold |

|---|---|---|

| Liner surface finish | Surface profilometer (Ra) | ≤0.8μm for ceramic liners |

| Piston alignment | Dial indicator | <0.3mm runout |

| Seal integrity | Pressure decay test (API 7K) | <5% pressure drop in 30min |

Winter Precautions: Drain fluids below 0°C to prevent ceramic liner cracking from ice expansion.

Common Issues and Solutions

| Problem | Root Cause | Solution |

|---|---|---|

| Liner scoring | Abrasive particles (>21% solids) | Replace with zirconia liners (3x longer lifespan) and install 10μm filters |

| Pressure loss | Worn piston seals | Use dual-durometer urethane pistons rated for 240°F+ (Forum Energy Technologies) |

| Corrosion pitting | H₂S exposure (>50ppm) | Switch to INCONEL® C-276 liners with 50ppm H₂S tolerance |

| Thermal cracking | Rapid temperature swings | Implement 16°C cooling systems for ceramic liners |

Advanced mud pump with precision-installed liners and optimized maintenance access

For severe wear patterns, conduct vibration analysis to detect misalignment >0.2mm, which accelerates liner degradation by 300% (PDFTechnical analysis of the failures in a typical drilling mud pump).

Top Manufacturers and Product Innovations

The global mud pump liner market is dominated by specialized manufacturers that combine advanced material science with precision engineering. Leading players like National Oilwell Varco (NOV), BOMCO, and Forum Energy Technologies collectively control over 60% of the market share (Top 10 Leading Mud Pump Liner manufacturers in the world). These companies differentiate through proprietary material formulations, smart monitoring systems, and region-specific product adaptations to meet diverse drilling challenges.

NOV and BOMCO

National Oilwell Varco (NOV) maintains technological leadership with its Mission-branded fluid ends and liner retention systems. Key innovations include:

- Blak-JAK Hydraulic Retention: Reduces liner replacement time by 75% through spring-loaded clamping mechanisms (Mission Blak-JAK Equipment – NOV)

- FD-1600 Series: Features 7″ bore liners with metal-to-metal sealing capable of 10,000 psi cyclic pressure (Mud Pumps, Fluid Mixing, & Processing Systems – Drilling | NOV)

- Smart Liner Monitoring: Embedded IoT sensors track wear patterns with 92% prediction accuracy (Mud Pump Liner Market’s Evolutionary Trends 2025-2033)

BOMCO (Baoji Oilfield Machinery) excels in cost-competitive solutions for Asian markets:

| Feature | BOMCO F1600HL Liners | Industry Standard |

|---|---|---|

| Material | ZTA Ceramic (ZrO₂-Al₂O₃) | High-Chrome Iron |

| Hardness | HRA92 | HRC65 |

| Service Life | 3,000+ hours | 800-1,200 hours |

| Pressure Rating | 7,500 psi | 5,000 psi |

| Cost/Hour Operation | $0.23 | $1.05 |

Data from Understanding the Importance of BOMCO Mud Pump Liners and Mud Pump Liners Market Research

BOMCO’s centrifugal casting process achieves 27% chromium distribution uniformity in bi-metal liners, extending lifespan by 40% compared to conventional methods (BOMCO Mud Pump F1600 Liner).

Innovations in Liner Technology

Smart Liners with Embedded Sensors Forum Energy Technologies leads in IoT-enabled liners featuring:

- MEMS strain gauges monitoring wall thickness loss in 0.01mm increments

- Wireless data transmission via LoRaWAN networks

- Predictive algorithms reducing unplanned downtime by 30% (Fluid End Pump Parts & Accessories – Forum Energy Technologies)

Eco-Friendly Materials Recent advancements include:

Recycled Metal Matrix Composites

- Incorporate 30-40% post-industrial scrap metal

- Maintain ≥900,000 psi tensile strength

- 20% lower carbon footprint vs. virgin materials (New materials, new advantages: the revolution in Mud Pumps)

Bio-Derived Ceramics

- Zirconia-alumina hybrids with graphene additives

- Stable to 350°C with 16% higher fracture toughness

- Comply with EU Circular Economy Standards (Ceramic Mud Pump Liner 2025 Trends)

Manufacturing Process Breakthroughs

- Additive Manufacturing: 3D-printed gradient materials combine steel cores (HRC60) with ceramic surfaces (HRA90) (US4603062A – Pump liners)

- Cold Spray Deposition: Applies 500μm wear-resistant coatings at 800m/s particle velocity, reducing material waste by 65% (Leading Mud Pump Parts Manufacturers Revolutionize the Market)

The market is projected to reach $840 million by 2033, with ceramic liners capturing 45% share as operators prioritize durability and smart monitoring capabilities (Mud Pump Liner Market Size And Projections).

Market Trends and Future Outlook

The mud pump liner market is undergoing significant transformation, driven by evolving drilling technologies and material science advancements. Valued at 450millionin2024,thesectorisprojectedtoreach450millionin2024,thesectorisprojectedtoreach650 million by 2033 at a 5% CAGR (Mud Pump Liner Market Size And Projections), with ceramic liners expected to capture 45% market share as operators prioritize durability and smart monitoring capabilities.

Regional Demand Analysis

North America dominates with 35% market share, fueled by shale gas extraction and HPHT drilling activities. Key developments include:

- Permian Basin operators reporting 38% longer ceramic liner lifespan vs. Gulf of Mexico deployments due to lower chloride content

- Adoption of IoT-enabled liners with 92% fault prediction accuracy in 78% of new rig deployments (Mud Pump Liner Market’s Evolutionary Trends 2025-2033)

Asia-Pacific exhibits the fastest growth (14% CAGR), led by:

- China’s BOMCO capturing 28% of OEM-compatible liner sales

- India’s offshore expansion driving demand for 7,500 psi-rated bi-metal liners

| Region | Market Share | Key Driver | Preferred Liner Type |

|---|---|---|---|

| North America | 35% | Shale gas modernization (250+ new rigs in 2025) | Zirconia ceramic (45% share) |

| Middle East | 25% | Ultra-deep well projects (>15,000 psi requirements) | Nickel-based alloys |

| Asia-Pacific | 20% | $6B offshore investments in South China Sea | Bi-metal (62% adoption) |

| Latin America | 10% | Pre-salt field developments (Brazil) | Ceramic-steel hybrids |

Data compiled from Mud Pump Liner Market Regional Analysis and 2025 Mud Pump Liners Market Research

Emerging markets show divergent material preferences:

- Africa: 80% of liners are conventional chrome alloys due to cost constraints

- Arctic regions: Low-temperature ceramics (-50°C capability) gaining 30% annual growth

Future Technologies

Graphene-Enhanced Ceramics represent a breakthrough, with field tests demonstrating:

- 40% higher fracture toughness vs. standard zirconia

- 500°C thermal stability for geothermal applications

- 16% lower friction coefficients through nanocoatings (Ceramic Mud Pump Liner 2025 Trends)

Manufacturing innovations include:

Additive Manufacturing

- Gradient materials combining HRC60 steel cores with HRA90 ceramic surfaces

- 65% material waste reduction via cold spray deposition at 800m/s

Smart Liners 2.0

- MEMS sensors monitoring wear in 0.01mm increments

- LoRaWAN networks enabling real-time pressure mapping

- Predictive algorithms reducing unplanned downtime by 30% (Fluid End Pump Parts – Forum Energy Technologies)

Sustainability Initiatives are reshaping material choices:

- Recycled Metal Composites: Incorporating 30-40% post-industrial scrap while maintaining ≥900,000 psi tensile strength

- Bio-Derived Ceramics: Meeting EU Circular Economy Standards with 20% lower carbon footprint

- Phase-Change Thermal Buffers: Eliminating external cooling fluids in 70% of geothermal applications

Regulatory impacts are accelerating adoption:

- API 7K-25 Revision: Mandating lifecycle assessments for liner materials by 2027

- EPA Guidelines: Requiring H₂S-resistant liners for all offshore operations

- Carbon Credit Programs: Offering $8-12/ton CO₂ credits for extended-life liners

The convergence of these technologies positions mud pump liners as strategic components for achieving drilling efficiency, cost control, and sustainability targets in the coming decade.

Conclusion and Recommendations

Final Thoughts

The selection of mud pump liners is a critical decision that directly impacts drilling efficiency, operational costs, and equipment longevity. As demonstrated throughout this report, the optimal liner material must align with specific drilling conditions to balance performance and cost-effectiveness. Key considerations include:

Material-Specific Advantages

- Ceramic liners (HRA85-92 hardness) excel in HPHT/abrasive environments but require 5-8× higher initial investment (Revolutionary Ceramic Liners Transform Mud Pump Performance)

- Nickel alloys provide unmatched H₂S resistance (50+ ppm) for sour gas wells but exhibit lower wear resistance than ceramics (Corrosion of nickel in acid solutions)

- Bi-metal liners offer the best cost-performance balance for medium-abrasive shale drilling at $2.50/hour operational cost (Bimetal Lined With High Chrome Alloy Pipe)

Operational Parameters

Condition Recommended Liner Key Benefit >15% abrasive solids Zirconia ceramic 10x lifespan vs. steel >50 ppm H₂S INCONEL® C-276 50 ppm H₂S tolerance -50°C Arctic drilling Nickel-based alloys Ductility at cryogenic temperatures <5,000 psi shallow wells Single-metal (HRC55-60) 30% cost savings vs. bi-metal Total Cost of Ownership

Ceramic liners achieve cost parity with bi-metal after 1,900 service hours in ultra-deep wells, while nickel alloys justify premium pricing only in extreme corrosion environments (Mud Pump Liners: 5 Key Factors).

Proactive maintenance aligned with API 7K standards—including ultrasonic thickness monitoring and pressure decay testing—can extend liner lifespan by 40-60%, significantly reducing fluid end maintenance costs. Operators should prioritize smart liner technologies with embedded IoT sensors, which reduce unplanned downtime by 30% through predictive wear analytics (Mud Pump Liner Market’s Evolutionary Trends 2025-2033).

Ultimately, the right liner choice combines technical specifications with operational realities, ensuring drilling efficiency while minimizing lifecycle costs in an increasingly challenging energy landscape.